- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

For more detailed information including pricing, customization and shipping.

3105 aluminum plate is series of AL-Mn alloys, the commonly used tempers are O, H12, H14, H18, H22, etc. 3105 aluminum magnesium manganese plate is a very good rust-proof aluminum alloy, has good electrical conductivity and mechanical properties, good deep drawing performance and tensile strength, excellent corrosion resistance, excellent plasticity and process performance, and has excellent performance in gas cutting and arc welding. Click to Order

The compressive strength of 3105 aluminum plate is slightly higher than that of 3003 aluminum plate, and its other properties are similar to those of 3003 aluminum alloy profiles. 3105 aluminum plate has excellent electrical conductivity, and the electrical conductivity can reach 41% due to 0.3% copper element is added to it. The 3105 aluminum plate has high plasticity under quenching conditions, and the plasticity is still stronger in semi-chilled hard bottoming, low plasticity, excellent corrosion resistance, excellent electric welding and poor drilling performance under cold hard bottoming.

|

Alloy |

3105 |

|

Temper |

O,H12,H14,H16, |

|

Thickness (mm) |

1.0-500 |

|

Width (mm) |

100-2650 |

|

Length (mm) |

500-16000 |

|

Package |

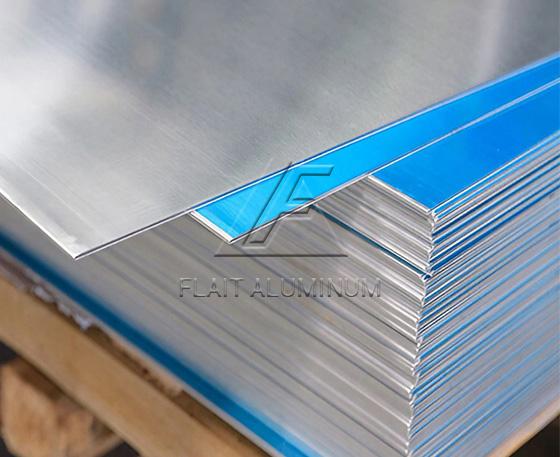

Export packaging (protective film, interleaved paper) |

|

Application |

Wine bottle caps, beverage bottle caps, |

Chemical Composition:

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Zn |

Ti |

Others |

Al |

|

3105 |

≤0.6 |

≤0.7 |

≤0.3 |

0.3-0.8 |

0.2-0.8 |

≤0.40 |

≤0.10 |

≤0.15 |

Remainer |

Mechanical properties:

|

Alloy |

Temper |

Thickness(mm) |

Tensile strength |

Elongation(%) |

Earing ratio (%) |

|

3105 |

H14,H24 |

0.2-0.5 |

150-200 |

2 |

4 |

|

3105 |

H16,H26 |

0.2-0.5 |

175-225 |

1 |

4 |

|

3105 |

H18 |

0.2-0.5 |

≥195 |

1 |

4 |

The deep drawing performance of the 3105 aluminum plate in the O temper is better than the deep drawing performance in the H26 temper, and the deep drawing performance of the 3105 aluminum before cryogenic treatment is better than that after 24h.

The deep drawing performance of the 3105 aluminum plate in the O temper is better than the deep drawing performance in the H26 temper, and the deep drawing performance of the 3105 aluminum before cryogenic treatment is better than that after 24h. 3105 aluminum plate has high plasticity in the annealed state, good plasticity in semi-cold work hardening, low plasticity in cold work hardening, and poor machinability.

3105 aluminum plate has high plasticity in the annealed state, good plasticity in semi-cold work hardening, low plasticity in cold work hardening, and poor machinability. 3105 aluminum alloy has excellent weldability and is suitable for all existing welding technologies, of which arc welding is the best method.

3105 aluminum alloy has excellent weldability and is suitable for all existing welding technologies, of which arc welding is the best method. The cold workability of 3105 aluminum alloy is very good even under cold tempering conditions. For all tempers, the bending radius of aluminum 3105 plate, which is no more than 1/16 inch thick, can range from 1/2 to 1.

The cold workability of 3105 aluminum alloy is very good even under cold tempering conditions. For all tempers, the bending radius of aluminum 3105 plate, which is no more than 1/16 inch thick, can range from 1/2 to 1. 3105 Aluminum sheet has good corrosion resistance, good anodic oxidation, poor machinability, etc.

3105 Aluminum sheet has good corrosion resistance, good anodic oxidation, poor machinability, etc. 3105 aluminum plate has good anti-rust performance, and it is applied to various bottle and can lids, which can achieve the effect of making the appearance of bottles and cans beautiful for a long time.

3105 aluminum plate has good anti-rust performance, and it is applied to various bottle and can lids, which can achieve the effect of making the appearance of bottles and cans beautiful for a long time. The surface quality of 3105 aluminum plate is good, no oil spots, waves, scratches, roll marks, neat trimming, no burrs.

The surface quality of 3105 aluminum plate is good, no oil spots, waves, scratches, roll marks, neat trimming, no burrs.3105 aluminum plate is mainly used for bottle stoppers, beverage bottle caps, skin care product caps, etc. Industrial applications include house baffles, partitions, movable house panels, gutters and drains, plastic sheet forming components, bottle caps, and more.