- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

For more detailed information including pricing, customization and shipping.

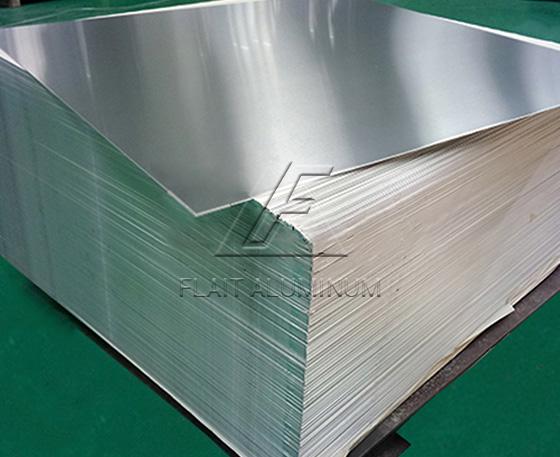

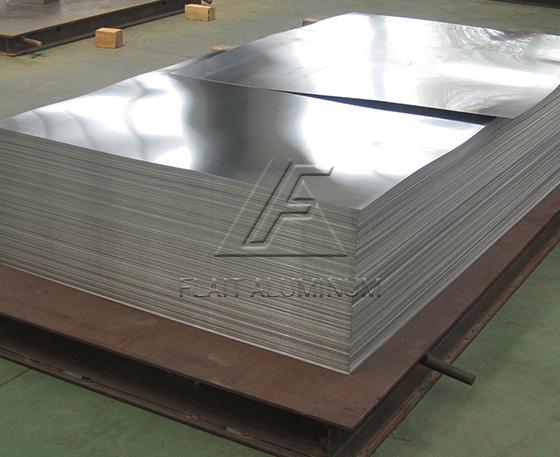

1100 aluminum plate is a common industrial pure aluminum alloy plate with an aluminum content of 99%. It is not high in strength and cannot be strengthened by heat treatment. However, it has good ductility and formability, is easy to weld and is corrosion-resistant. The corrosion resistance can also be further improved through anodization. 1100 aluminum plates are often used in processing parts that require good formability and high corrosion resistance but do not require high strength. They are widely used in the manufacturing of food industry equipment, storage containers, pressure tanks, cookware, and thin plate processing parts.

|

Alloy |

1100 |

|

Temper |

O,H12,H14,H16, H18,H19,H22,H24, H26,H28,H32,H34, H36,H38,etc. |

|

Thickness (mm) |

0.1-500 |

|

Width (mm) |

20-2650 |

|

Length (mm) |

500-16000 |

|

Package |

Export packaging (protective film, interleaved paper) |

|

Application |

Aluminum plastic panels, bus doors, cooking utensils, |

Chemical composition:

|

Si + Fe |

0.95 |

|

Cu |

0.05-0.20 |

|

Zn |

0.1 |

|

Mn |

0.05 |

|

Al |

99 |

Mechanical properties:

|

Alloy |

Temper |

Thickness(mm) |

Tensile strength(Mpa) |

Elongation(%) |

|

1100 |

O |

>0.2-0.5 |

75-105 |

≥20 |

|

>0.5-1.0 |

≥25 |

|||

|

>1.0-4.5 |

≥30 |

|||

|

H22 |

>0.2-0.5 |

95-130 |

≥10 |

|

|

>0.5-1.0 |

≥12 |

|||

|

>1.0-4.5 |

≥15 |

|||

|

H24 |

>0.2-0.5 |

110-145 |

≥6 |

|

|

>0.5-1.0 |

≥8 |

|||

|

>1.0-4.5 |

≥10 |

|||

|

H26 |

>0.2-0.5 |

≥2 |

||

|

>0.5-1.0 |

≥3 |

|||

|

>1.0-4.5 |

≥4 |

|||

|

H18 |

>0.2-0.5 |

≥150 |

≥1 |

|

|

>0.5-1.0 |

≥2 |

|||

|

>1.0-4.5 |

≥3 |

|||

|

H112 |

>4.5-6.5 |

≥95 |

≥9 |

|

|

>6.5-12.5 |

≥90 |

≥9 |

||

|

>12.5-50 |

≥85 |

≥14 |

||

|

>50-80 |

≥80 |

≥20 |

1100 aluminum sheet plate has good corrosion resistance, excellent thermal conductivity and electrical conductivity.

1100 aluminum sheet plate has good corrosion resistance, excellent thermal conductivity and electrical conductivity. 1100 aluminum sheet plate has good welding performance and can be gas welded, arc welded, contact spot welded, wire welded, and brazed.

1100 aluminum sheet plate has good welding performance and can be gas welded, arc welded, contact spot welded, wire welded, and brazed. 1100 aluminum sheet plate has good formability and cutting processability, and is easy to withstand various pressure processing, stretching and bending.

1100 aluminum sheet plate has good formability and cutting processability, and is easy to withstand various pressure processing, stretching and bending. 1100 aluminum sheet plate has low strength and cannot be strengthened through heat treatment.

1100 aluminum sheet plate has low strength and cannot be strengthened through heat treatment.1100 aluminum plate is generally used in heat sinks, bottle caps, printing plates, cooking utensils, building materials, heat exchanger components, and can also be used as food and chemical handling and storage equipment, sheet metal products, hollow hardware processed by drawing and spinning, Welding combination keys, reflectors, nameplates, and deep-drawn products.