- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

For more detailed information including pricing, customization and shipping.

![]() Hydrophilic Aluminum Foil For Air Conditioner Heat Exchanger

Hydrophilic Aluminum Foil For Air Conditioner Heat Exchanger

Air conditioning aluminum foil, also known as aluminum foil fins, is a special material for manufacturing heat exchanger fins for air conditioners. The air conditioner foil used in the early days was ordinary aluminum foil. In order to improve the surface properties of the ordinary aluminum foil, it is coated with anti-corrosion coating and hydrophilic coating before forming to form a hydrophilic aluminum foil, which is widely used in household industrial air conditioners, refrigerators, automobile air conditioners and other refrigeration equipment. In addition, there is another kind of hydrophobic aluminum foil, which makes the surface of the fins have a hydrophobic function and prevents condensation from sticking, it is mainly used in dryers to improve heating efficiency.

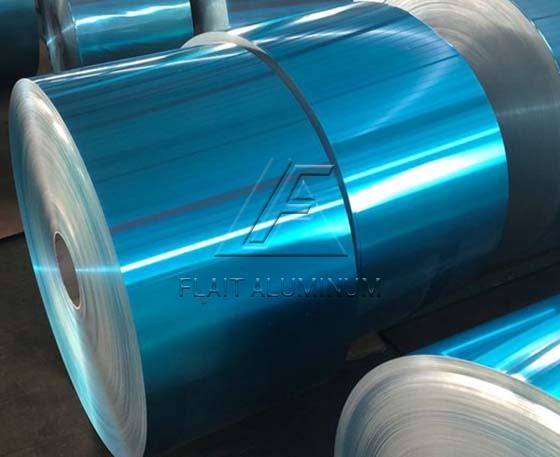

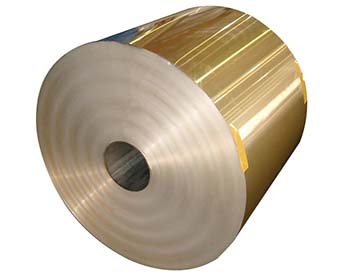

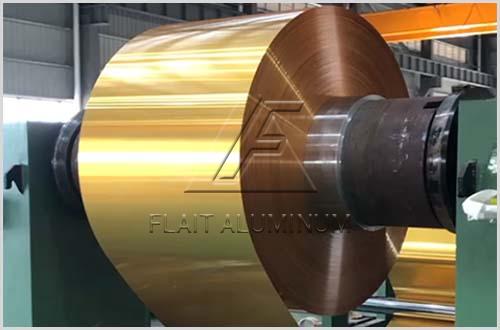

Air conditioner aluminum foil is used as heat-conducting fin material for air-conditioning heat exchangers. It has the advantages of low density, good thermal conductivity, easy processing, odorless, environmental protection and low price. Hydrophilic aluminum foil can be surface-coated, usually blue and gold-plated. The main aluminum foils for air conditioning are: 8006 hydrophilic aluminum foil, 8011 hydrophilic aluminum foil, 3102 hydrophilic aluminum foil, 1100 hydrophilic aluminum foil, etc.

8011 Hydrophilic aluminum foil and 8006 hydrophilic aluminum foil are mainly used in the production of heat exchanger fins, such as condensers and evaporators of air conditioner, refrigerator, automotive air-conditioning, etc. 8011 aluminum foil is added with Al-Fe-Si elements. Its performance is better than pure aluminum foil. Aluminum foil fin heat exchangers mostly use 8011 aluminum alloy. The commonly used tempers are 8011-O hydrophilic aluminum foil and 8011-H22 hydrophilic aluminum foil.The iron content of 8006 hydrophilic aluminum foil is higher than 8011 hydrophilic aluminum foil, and the performance is slightly better. 8006 aluminum foil has a higher tensile strength than 8011 aluminum foil, which can reach 125-135; also, the cup convexity and elongation of 8006 aluminum foil are higher than 8011 aluminum foil.

3102 Aluminum foil has the characteristics of high strength, oxidation resistance, corrosion resistance, and not easy to deform. It is an excellent product for making aluminum foil for air conditioners such as radiators, heat exchangers. 3102 Air-conditioning aluminum foil is used as heat-conducting fin material for air-conditioning heat exchangers. It has the advantages of low density, good thermal conductivity, easy processing, odorless, environmentally friendly and low price. 3102 Hydrophilic aluminum foil is widely used in household air conditioners, refrigeration cabinets and other refrigeration equipment, automobile air conditioners and water tanks.

Tempers: O/HO,H22,H24,H26

Applications: Coolers, condensers, evaporators

Tempers: HO/O, H22, H24, etc.

Applications: Heat exchanger fin stock

Tempers: H26,etc.

Applications: Air conditioners, refrigerators

Tempers: H22

Applications: Heat exchanger fins for air conditioners

Tempers: H26

Applications: Air Conditioner

|

Alloy |

Temper |

Thickness(mm) |

Width(mm) |

Inner Diameter (mm) |

Color |

Sleeve Material |

|

1100 3102 1030B 8011 8006 |

O/HO H22 H24 H26 H18 |

0.08-0.20 |

100-1250 |

¢75,¢150, ¢200,¢300, ¢400,¢500 |

Blue, gold/golden, green,rose red, etc. |

Aluminum, carbon, steel |

| Chemical Composition | |||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | OTHERS | AL | |

| SINGLE | TOTAL | ||||||||||

| 1100 | Si+Fe:0.95 | 0.05-0.20 | 0.05 | - | - | 0.1 | - | 0.05 | 0.15 | 99% | |

| 1030B/3102 | 0.2 | 0.3 | 0.1 | 0.3 | 0.05 | 0.05 | 0.1 | 0.08 | 0.2 | Balance | |

| 8011 | 0.5-0.9 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | 0.08 | 0.05 | 0.15 | Balance |

| 8006 | 0.4 | 1.2-2.0 | 0.3 | 0.3-1.0 | 0.1 | - | 0.1 | - | 0.05 | 0.15 | Balance |

| Tensile Strength | ||

| Alloy | Temper | Mechanical Performance under room temperature Tensile Strength (σb, Mpa) |

| 1100 | O | 60-115 |

| H22 | 90-135 | |

| H24 | 110-160 | |

| H26 | 125-180 | |

| H18 | ≥140 | |

| H19 | ≥150 | |

| 8011 | O | 60-110 |

| H22 | 90-150 | |

| H24 | 120-170 | |

| H26 | 140-190 | |

| H18 | ≥150 | |

| H19 | ≥160 | |

| 1030B/3102 | H26 | 125-145 |

| 8006 | O | 90-140 |

| Punching | ||||

| Alloy & Temper | Thickness (mm) | Punching Speed/min | Collar Diameter (min) | Collar Height (mm) |

| 1100/8011/8006 & O/H22 | 0.09-0.10 | 160-250 | 9.52 | ≥1.8 |

| 0.101-0.12 | 160-251 | 9.52 | ≥2.0 | |

| 0.121-0.14 | 160-252 | 9.52 | ≥2.8 | |

| 0.141-0.16 | 120-200 | 9.52 | ≥3.7 | |

| 0.161-0.18 | 120-201 | 9.52 | ≥4.5 | |

| 0.181-0.2 | 120-202 | 9.52 | ≥5 | |

| 0.181-0.2 | 100-160 | 15.88 | ≥5.5 | |

| 0.201-0.22 | 100-160 | 15.88 | ≥5.7 | |

| 0.221-0.25 | 100-160 | 15.88 | ≥6.0 | |

| 0.251-0.28 | 100-160 | 15.88 | ≥6.8 | |

| 0.281-0.30 | 100-160 | 15.88 | ≥8.0 | |

| 0.3-0.35 | 100-160 | 15.88 | ≥10.0 | |

| 1030B/3102 | 0.095-0.0105 | 180-300 | 7/9.52 | ≥1.6 |

| Hydrophilic Coating | ||

| No. | Item | Description |

| 1 | Bottom Coating | Epoxy Resin |

| Surface Coating | Acrylic Resin | |

| 2 | Film Thickness | 2.4-2.6µm(Single side average thickness) |

| 3 | Hydrophilic | Primary Contact angle ≤10° |

| Continuous Contact ≤20° | ||

| 4 | Adherence | Erichsen test (Press Depth 5mm): No peeling |

| Gridding test (100/100): No plunger separation | ||

| 5 | Corrosion resistance | Salt spray test (500hours) |

| 6 | Alkali resistance | Dipped in 20% NaOH in 20℃ for 3 minutes, absolutely no blister |

| 7 | Impregnant resistance | Sample’s weight loss≤1% |

| 8 | Heat resistance | Under 200℃ for 5 minutes, performance and color unchanged |

| Under 300℃ for 5 minutes, the coating film becomes a little yellow | ||

| 9 | Oil Proof | Dipped in volatile oil for 24 hours, no blister on the coating film |

| 10 | Odor of the coating film | No odor |

| 11 | Abrasion to mould | Same with ordinary aluminum foil |

Excellent hydrophilicity and corrosion resistance;

Excellent hydrophilicity and corrosion resistance; Good formability and no wear to the mold;

Good formability and no wear to the mold; Strong stamping oil resistance, solvent resistance, heat resistance;

Strong stamping oil resistance, solvent resistance, heat resistance; No color change, no terrible smell;

No color change, no terrible smell; The condensed water accumulated on the surface of the heat exchange fins is evenly distributed on the surface, and the accumulation and blockage between the heat exchange fins will not be caused by the formation of water droplets, which will affect the heat exchange conditions, thereby increasing the heat exchange rate by 5%;

The condensed water accumulated on the surface of the heat exchange fins is evenly distributed on the surface, and the accumulation and blockage between the heat exchange fins will not be caused by the formation of water droplets, which will affect the heat exchange conditions, thereby increasing the heat exchange rate by 5%; Since the water has no beads, the noise caused by vibration is correspondingly reduced.

Since the water has no beads, the noise caused by vibration is correspondingly reduced.

Air conditioner

Air conditioner Refrigerator

Refrigerator Indoor and outdoor heat exchanger

Indoor and outdoor heat exchanger Radiator

Radiator Ventilation systems

Ventilation systems Heating and cooling systems

Heating and cooling systems Thermal rotors

Thermal rotors Coolers

Coolers Evaporators

Evaporators