- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

For more detailed information including pricing, customization and shipping.

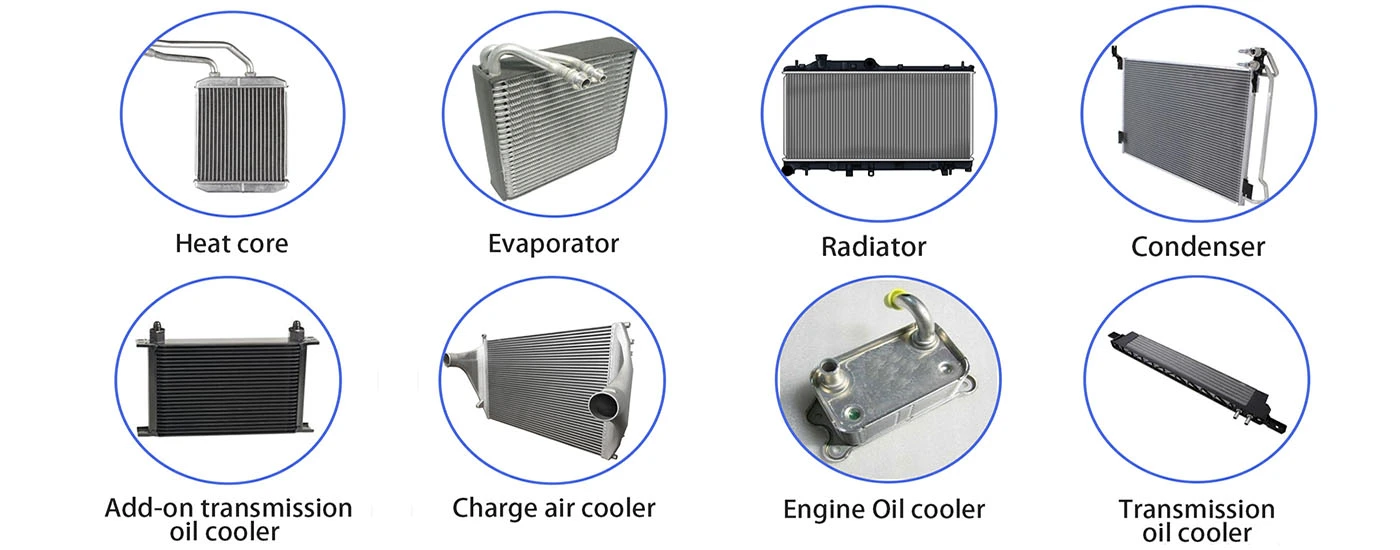

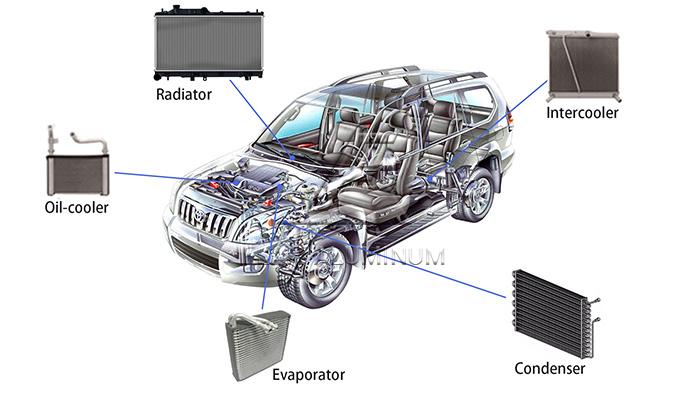

Brazing aluminum sheet is also called aluminum alloy brazing sheet, aluminum brazing sheet, aluminum brazing composite sheet, aluminum brazing cladding sheet, etc., which belongs to a kind of aluminum sheet commonly used in industrial production. The main products of brazed aluminum sheets are 3xxx and 4xxx series aluminum alloy sheets. Brazed aluminum sheets are used in the fields of radiators for electronic appliances and automobile industry, such as: air conditioner condensers, radiators, radiators for electronic components, etc. Commonly used alloys for brazing aluminum plates coils strips are: 4045/3003, 4343/3003, 4045/3003/4045, 4343/3003/4343, 4343/3003/7072 and etc.

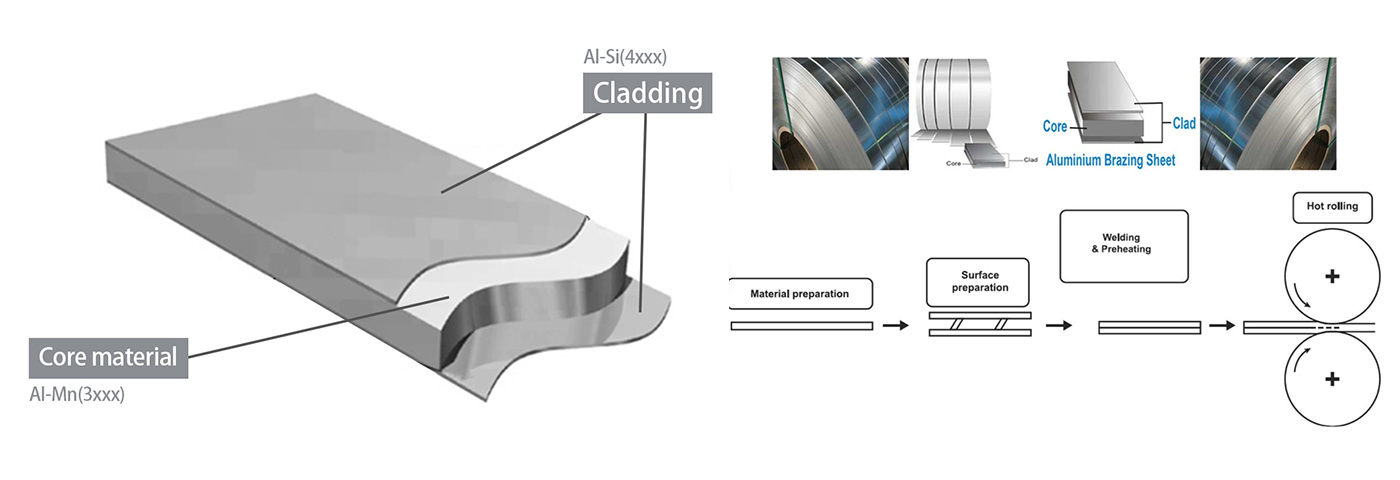

Flait Aluminum uses surface pretreatment process to mill the base/core alloys and cladding layer alloys ingots to ensure that there are no defects such as deep grooves, aluminum chips, slag inclusions, surface cracks, etc., and use physical and chemical methods to strictly clean the oil, dust and metal oxide film on the surface of the aluminum plate. Under the premise of ensuring the product quality, the aluminum brazing cladding sheet produced has no pores, cracks, welding tumors, etc., and has a bright surface, uniform weld and beautiful appearance.

|

Alloy |

Core 3003 3003+Zn 3003MOD |

Brazing clad for CAB 4343 4045 4047 |

Brazing clad for VAC 4104 4A13 |

Contact-water clad 7072 |

|

Temper |

O,H12,H14,H16,H18,H22,H24,H26 |

|||

|

Thickness (mm) |

0.5~5.0mm |

|||

|

Width (mm) |

500-1200mm |

|||

|

Length (mm) |

C |

|||

|

Clad Rate |

4-18% per side, or customer requested |

|||

|

Tensile Strength (MPa) |

Depending on different material/temper |

|||

|

Yield Strength (MPa) |

Depending on different material/temper |

|||

|

Elongation (%) Min |

Depending on different material/temper |

|||

|

Packing |

Export standard package |

|||

|

Normal Alloys Plates |

4045/3003, 4343/3003, 4045/3003/4045, 4343/3003/4343, 4343/3003/7072 and etc. |

|||

| Mechanical Property of Brazing Aluminum Sheet Coil Strip | ||||||||

| Alloy | Temper |

Thickness (mm) |

Tolerance (mm) |

Clad Ratio (%) |

Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%)Min | Application |

| 3003 | H14 | 0.06~0.1 | ±0.005 | None | 150~200 | ≥120 | 1 | Radiator fin and plate |

| 4043/3003/4043 | H14 | 0.06-0.1 | ±0.005 | 8-12 | 150-200 | ≥120 | 1 | |

| 4045/3003/4045 | H14 | 0.1~0.12 | ±0.005 | 8-12 | 150-200 | ≥120 | 1 | Charge air cooler material |

| 4343/3003 | O | 1.2-3.0 | ±0.03 | 5-10 | 100-150 | ≥45 | 25 | Radiator fin and plate |

| 4343/3003/7072 | O | 1.2-3.0 | ±0.03 | 5-10 | 100~150 | ≥45 | 25 | |

| 4343/3003/4343 | O | 0.4-0.5 | ±0.02 | 8-12 | 100-150 | ≥45 | 27 | Evaporator fin and plate |

| 4045/3003/4045 | O | 0.8-1.2 | ±0.03 | 8-12 | 100-150 | ≥45 | 27 | |

| 4045/3003/4045 | O | 0.5-0.8 | ±0.02 | 15-20 | 100-150 | ≥45 | 25 | Oil cooler |

| 4104/3003/4104 | H14 | 0.6-0.8 | ±0.02,±0.03 | 13-17,8~12 | 150-200 | ≥120 | 3 | Engineering machinery |

| 4004/3003/4004 | H14 | 0.6~0.8,1.2~1.5 | ±0.02 ±0.03 | 13-17 8-12 | 150-200 | ≥120 | 3 | |

| Note: Alloy, specification and mechanical property can be customized according to different requirements. | ||||||||

| Alloy solidus/liquidus temperature and recommended brazing temperature | ||||||||

| Aluminum Alloy | Core | Brazing Clad | ||||||

| 3003 | 3003+Zn 3003+MOD | 7072 | 4343 | 4045 | 4047 | 4A13 | 4104 | |

| Solidus Temperature /℃ | 643 | 641 | 646 | 577 | 577 | 577 | 577 | 559 |

| Liquidus Temperature /℃ | 654 | 653 | 657 | 615 | 590 | 580 | 615 | 591 |

| Recommended Brazing Temperature /℃ | - | - | - | 600-620 | 590-605 | 580-605 | 600-620 | 590-605 |

High strength and excellent welding performance; good mechanical property and surface condition.

High strength and excellent welding performance; good mechanical property and surface condition. Good heat resistance and high temperature resistance, and has a certain corrosion resistance.

Good heat resistance and high temperature resistance, and has a certain corrosion resistance. Excellent processing performance, small deformation and easy forming; excellent collapse resistance during brazing.

Excellent processing performance, small deformation and easy forming; excellent collapse resistance during brazing. There are no pores, cracks and other phenomena in the welding, the surface of the welded joint is bright, and the fillet is even.

There are no pores, cracks and other phenomena in the welding, the surface of the welded joint is bright, and the fillet is even. Flait Aluminum provides various specifications for fin and brazing aluminum plate coil strip.

Flait Aluminum provides various specifications for fin and brazing aluminum plate coil strip.

◎Brazing layer material: Al-Si alloys (4xxx Series)

◎Core material: Al-Mn alloys (3xxx Series), Al-Si-Mg Alloys (6xxx Series)

◎Sacrificial anode material (Anticorrosive coating): AL-Zn-Cr alloy (7072)

Brazing aluminum sheets coils strips are widely used in the fields of dynamic heat exchangers such as new energy vehicles, construction machinery, rail transit, shipping and aviation, as well as static heat exchangers such as household air conditioners, commercial refrigeration, industrial heat exchange, and so on.

Brazing aluminum sheets coils strips are widely used in the fields of dynamic heat exchangers such as new energy vehicles, construction machinery, rail transit, shipping and aviation, as well as static heat exchangers such as household air conditioners, commercial refrigeration, industrial heat exchange, and so on.  Typical application of brazing aluminum sheets coils strips is: radiator system and air conditioning system of traditional fuel vehicles and new energy vehicles.

Typical application of brazing aluminum sheets coils strips is: radiator system and air conditioning system of traditional fuel vehicles and new energy vehicles.