- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

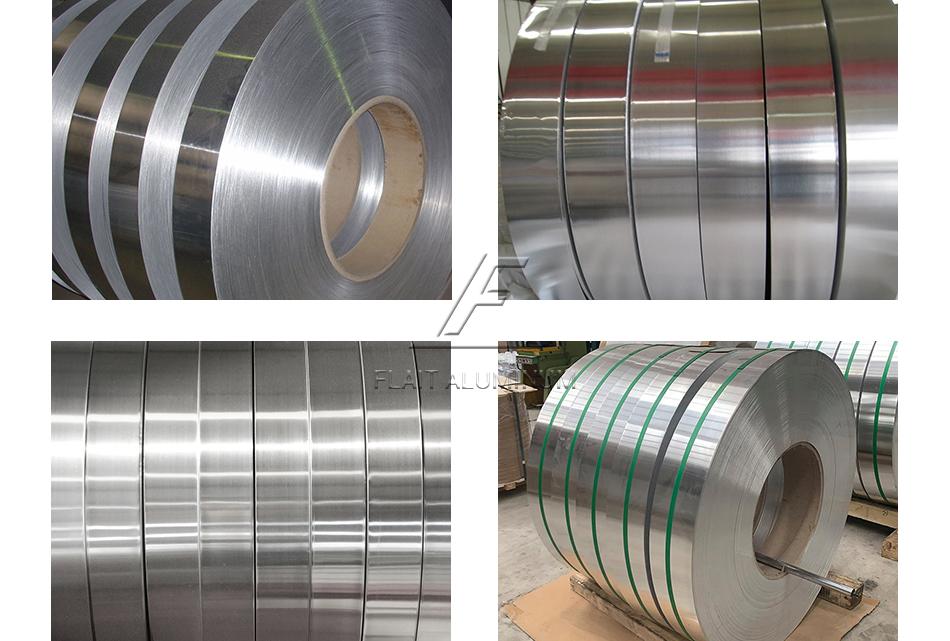

Pure aluminum strip is the key raw material for manufacturing transformer windings. It has the characteristics of high conductivity, soft texture, smooth surface and no burrs. The aluminum strips for transformer windings are mainly 1 series aluminum alloys: 1060/1060A transformer aluminum strip, 1050/1050A transformer aluminum strip, 1070/1070A transformer aluminum strip, 1350 transformer aluminum strip. The temper is O/HO. Aluminum strip thickness is 0.08-3.00 mm. The most common one is 1060 transformer aluminum strip, which is mainly used as a conductive material in high and low voltage windings of dry-type transformers. 1060 Aluminum strip for transformers has the characteristics of small size, light weight, good insulation performance, no pollution, moisture-proof, and low maintenance cost. These characteristics make aluminum transformers widely used in high-rise buildings, underground facilities, commercial centers, residential areas, hotels, etc. Flait Aluminum has a large inventory of transformer aluminum strips. If you need transformer aluminum strips, please contact us and we will provide you with high-quality products and considerate services. Contact us to get a quote and free samples.

When slitting the transformer aluminum strip, the quality inspection personnel should pay more attention to whether there are scratches during the rolling process of the equipment, because if there are foreign matter in the equipment during the slitting process, it will cause the surface of aluminum coil to have scratches from beginning to end. So pay attention to scratches during the rewinding process, if scratches are found, stop production immediately and find out the cause. Usually scratches on aluminum strips almost always occur during the slitting process, and there are fewer problems with master batch. Therefore, slitting and processing employees must check and clean up foreign objects on the production line before processing. During production, pay attention to whether there are any defects on the surface of the aluminum strips, observe whether there are scratches on the surface of the aluminum strip during packaging. The burr-free aluminum strips for transformers after chamfering process have smooth and traceless surface, flat plate shape, neat cross-section and rounded corners with zero burrs.

There are impurities attached to the surface of the ingot or there are a certain number of hard metal particles in the ingot. There are a large number of segregation floating matter on the surface of the ingot and the ingot has not been homogenized or the homogenization treatment effect is not good. When metal flows through the work belt during the extrusion process, these segregated floating objects or hard metal particles adhere to the surface of the work belt or cause damage to the work belt, and ultimately cause scratches on the surface of the aluminum strip;

There are impurities attached to the surface of the ingot or there are a certain number of hard metal particles in the ingot. There are a large number of segregation floating matter on the surface of the ingot and the ingot has not been homogenized or the homogenization treatment effect is not good. When metal flows through the work belt during the extrusion process, these segregated floating objects or hard metal particles adhere to the surface of the work belt or cause damage to the work belt, and ultimately cause scratches on the surface of the aluminum strip; There are debris on the work belt, which will cause the surface of the work belt to be injured during extrusion and scratch the aluminum strip; when it comes into contact with the aluminum strip, it will scratch the surface of the aluminum strip;

There are debris on the work belt, which will cause the surface of the work belt to be injured during extrusion and scratch the aluminum strip; when it comes into contact with the aluminum strip, it will scratch the surface of the aluminum strip; There is exposed metal on the discharge track or swing bed, or there are hard inclusions in the graphite strips. The aluminum strip is damaged due to excessive speed;

There is exposed metal on the discharge track or swing bed, or there are hard inclusions in the graphite strips. The aluminum strip is damaged due to excessive speed; When the fork lever sends the aluminum strip from the discharge track to the material frame;

When the fork lever sends the aluminum strip from the discharge track to the material frame; Abrasions caused by artificial dragging of the aluminum strip on the material frame;

Abrasions caused by artificial dragging of the aluminum strip on the material frame; Damage caused by friction or extrusion between aluminum strips during transportation.

Damage caused by friction or extrusion between aluminum strips during transportation. Strengthen the control of aluminum ingot quality;

Strengthen the control of aluminum ingot quality; Minimize the contact damage between the aluminum strip and the assistive device.

Minimize the contact damage between the aluminum strip and the assistive device. Use soft felt to isolate the aluminum strip from the assistive devices. Try to prevent random dragging or flipping of the aluminum strip, and promptly clean up foreign objects on the felt.

Use soft felt to isolate the aluminum strip from the assistive devices. Try to prevent random dragging or flipping of the aluminum strip, and promptly clean up foreign objects on the felt. Handle them with care during production and try to prevent friction with each other.

Handle them with care during production and try to prevent friction with each other. Arrange the aluminum strips reasonably in the material frame.

Arrange the aluminum strips reasonably in the material frame.| Alloy | 1050,1060,1070,1350 |

| Temper | O/HO |

| Thickness (mm) | 0.08 – 3.00 |

| Width (mm) | 10 – 1500 |

| Conductivity (% IACS) | 1050-O ≥ 60% IACS 1060-O ≥ 61.5% IACS 1070-O ≥ 62.7% IACS 1350-O ≥ 62% IACS |

| Elongation (%) | ≥20 (Thickness: 0.08-0.20) ≥25 (Thickness: 0.20-3.00) |

| U. T. S | 60-95N/mm2 |

| Density in 20℃ | 2.703kg/m3 |

| Resistivity (Ω·mm² /m) | ≤0.02825 |

| Burr’s height | 0.01–0.03mm vary with thickness of the strip |

| Collapsed side’s height | 0.05–0.1mm |

| ID | Ø 150mm,Ø300mm,Ø400mm,Ø500mm |

| Surface | Smooth, free from scratches and impurities |

| Application | Transformer winding |

| Packing | Eye to wall and eye to sky, wooden pallet and wooden case |

| Sample | Available |

| Remark | Transformer aluminum strip can be customized |

Original Source: https://www.flait-aluminum.com/Transformer-Aluminum-Strip.html

Tags: 1060 transformer aluminum strip , 1350 transformer aluminum strip , 1050 transformer aluminum strip , 1070 transformer aluminum strip