- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

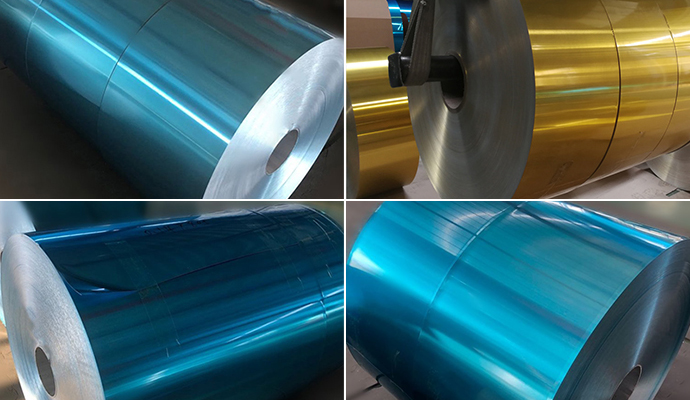

Air conditioning has become an indispensable household appliance in people’s lives. Air conditioners are gradually developing towards miniaturization, high efficiency and long life. The air conditioning heat exchanger fins are also developing in the direction of ultra-thin and high strength. In the 1980s, the thickness of heat exchange fins was 0.15-0.2mm, but today’s thickness is only between 0.09 and 0.15mm. Air conditioner aluminum foil is mainly used in the production of heat exchanger fins, such as condensers and evaporators of air conditioner, refrigerator, automotive, etc. The main hydrophilic aluminum foils for air conditioning are: 8006 hydrophilic aluminum foil, 8011 hydrophilic aluminum foil, 3102 hydrophilic aluminum foil, 1100 hydrophilic aluminum foil, etc.

| Specification of hydrophilic aluminum foil for air conditioner | ||||||

| Alloy | Temper | Thickness(mm) | Width(mm) | Inner Diameter(mm) | Color | Sleeve Material |

| 1100 3102 1030B 8011 8006 |

O/HO H22 H24 H26 H18 |

0.08-0.20 | 100-1250 | ¢75,¢150, ¢200,¢300, ¢400,¢500 |

Blue, gold/golden, green, rose red, etc. |

Aluminum, carbon, steel |

1. Uncoated aluminum foil

Uncoated aluminum foil refers to aluminum foil that has been rolled and annealed without any form of surface treatment. Currently, about 50% of the heat exchange fins used in many countries are uncoated aluminum foil.

2. Coated aluminum foil

Coated aluminum foil is to re-process the surface of uncoated aluminum foil to make it have certain special functions.

3. Corrosion-resistant aluminum foil

The surface of the corrosion-resistant aluminum foil product has a certain anti-corrosion protective layer. The air-conditioning heat exchanger made of this product can be used in harsher areas and can significantly extend the service life of the air conditioner. Also, due to the improvement of the corrosion resistance of the heat exchange fins, the generation of surface corrosion powder is greatly reduced, thereby improving the ventilation quality and purifying the air in the air-conditioned room.

4. Hydrophilic aluminum foil

The surface of hydrophilic aluminum foil has strong hydrophilicity. The quality of the hydrophilic property is determined by the angle formed by water sticking to the surface of the aluminum foil. The smaller the angle a, the better the hydrophilic property, and vice versa. Generally speaking, it is hydrophilic if the angle is less than 35°. Hydrophilic aluminum foil is generally used on the condenser of air conditioners. Its main function is to make the moisture in the hot air condense into water droplets on the heat exchanger, so that it can easily spread and flow downward along the sheet. This can prevent the ventilation effect of the heat exchanger from being affected by the “bridging” of water droplets between the heat exchange fins, thereby improving the heat exchange rate of the air conditioner and saving electricity under the same cooling capacity. In addition to its good hydrophilicity on the surface, hydrophilic aluminum foil also has high corrosion resistance, thereby optimizing the performance of the air conditioner.

5. Hydrophobic aluminum foil

Hydrophobic aluminum foil is also called water-repellent aluminum foil, and its surface properties are exactly the opposite of hydrophilic aluminum foil. That is, when the condensed water condenses onto the surface of the aluminum foil, the contact angle with the aluminum foil is relatively large, generally above 75°. The larger the angle, the better the water repellency. The ultimate purpose of using hydrophobic aluminum foil is the same as that of hydrophilic aluminum foil, which is to prevent condensation water from remaining between the heat exchange fins. The difference is that the hydrophobic aluminum foil removes the condensed water between the heat exchange fins by increasing the contact angle between the condensed water and the heat exchange fins, causing the condensed water to form water droplets that are easy to slide off.

6. Self-lubricating aluminum foil

During the processing of air-conditioning heat exchange fins, lubricating oil is generally added to the surface, then punched and flanged, and finally the lubricating oil is washed away with trichlorethylene. Since trichlorethylene is harmful to the human body, in order to reduce this process, self-lubricating aluminum foil was produced accordingly. Self-lubricating aluminum foil does not require separate lubricating oil during its punching process. The lubrication during punching is borne by a pre-treated film on the surface of the aluminum foil. Since there is no need to add special lubricating oil, the subsequent trichlorethylene cleaning and drying processes are also omitted.

7. Mildew-proof aluminum foil

Mildew-proof aluminum foil is mainly used in the indoor unit of the air conditioner. Its main function is to prevent the surface mold of the heat exchanger from being used or left for a long time, thereby significantly improving the ventilation quality of the air conditioner and preventing the generation of abnormal odors, effectively Improve the environment in air-conditioned rooms.

Original Source: https://www.flait-aluminum.com/Hydrophilic-Aluminum-Foil-For-Air-Conditioner-Heat-Exchanger.html

Tags: 8006 hydrophilic aluminum foil, 8011 hydrophilic aluminum foil, 3102 hydrophilic aluminum foil , 1100 hydrophilic aluminum foil