- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

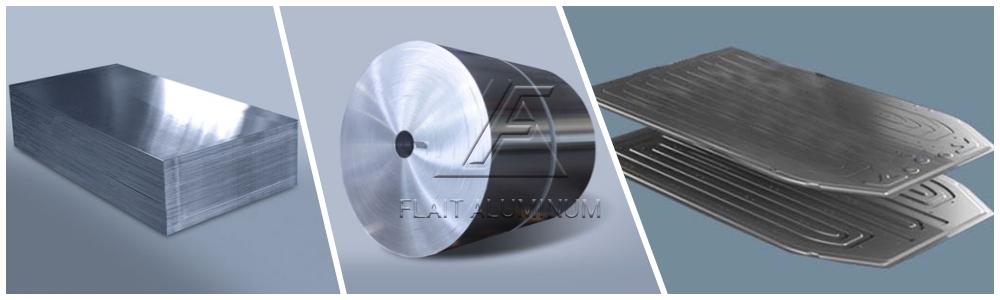

As the energy density and power density of new energy power batteries increase, the charge and discharge rate of the battery increases, and the calorific value of the battery also increases. The heat dissipation of the battery becomes a problem. Due to its better heat dissipation effect, the water-cooled plate has gradually become the mainstream heat dissipation method for batteries. Electric vehicle battery cooling plates are an important part of the thermal management system of electric vehicles and are often used in load-bearing, corrosion-resistant environments. The electric vehicle battery cooling plate is generally made of aluminum brazing composite material. In order to ensure its stamping and tensile requirements, the material used is required to have good tensile capacity.

3003 aluminum plate has good formability, good corrosion resistance and weldability. Flait Aluminum has developed a production process for brazed pre-composite materials and is currently able to custom produce aluminum coils for battery cooling plates. Product alloy grade: 3003 aluminum plate coil, 3003mod aluminum plate coil; composite aluminum coil: 3003+4045 brazing aluminum plate coil, 3003mod+4343 brazing aluminum plate coil. Flait Aluminum provides aluminum sheets in various thickness states, and the product size can be customized on demand.

| Alloy | 3003 | 3003 | 3003mod |

| Brazing clad for CAB | 4045 | 4343 | 4343 |

| Temper | O,H14 | ||

| Regular Thickness(mm) | 0.6–3.0 | ||

| Width(mm) | 12-1240 | ||

| Length(mm) | C | ||

| Clad Rate | 4-18% per side, or customer requested | ||

| ID | 75 150 200 300 500 | ||

| OD | Max 1800 | ||

| Coil Weight(kg) | Max 8000 | ||

| Packing | Export standard package | ||

| Normal Alloys Plates | 4045/3003, 4343/3003, 4045/3003/4045, 4343/3003/4343, 4343/3003/7072 and etc. | ||

| Typical Application | electric vehicle battery cooling plates | ||

| 4343 can be replaced by 4045/4047etc, according to customer’s requirement. Delivery status, performance, thickness and cutting width can be customized according to customer’s requirements. |

|||

Strong corrosion resistance: 3003 aluminum plate belongs to the aluminum-manganese alloy series and has excellent corrosion resistance.

Strong corrosion resistance: 3003 aluminum plate belongs to the aluminum-manganese alloy series and has excellent corrosion resistance. High strength: 3003mod has high strength and has excellent load-bearing capacity after brazing and compounding.

High strength: 3003mod has high strength and has excellent load-bearing capacity after brazing and compounding. Excellent heat dissipation power: 3003 aluminum plate and 4343 aluminum plate are brazed and composited, and the heat dissipation power is greater

Excellent heat dissipation power: 3003 aluminum plate and 4343 aluminum plate are brazed and composited, and the heat dissipation power is greater Strong stamping and stretching performance: 3003-O aluminum plate is soft, high plasticity, easy to stamping and stretching, and meets conventional processing requirements

Strong stamping and stretching performance: 3003-O aluminum plate is soft, high plasticity, easy to stamping and stretching, and meets conventional processing requirements Good stability: stable performance, high elongation, easy stamping, strong welding performance;

Good stability: stable performance, high elongation, easy stamping, strong welding performance; Light weight: Aluminum alloy has low density and light weight, which is an ideal lightweight material for automobiles.

Light weight: Aluminum alloy has low density and light weight, which is an ideal lightweight material for automobiles.

Original Source: https://www.flait-aluminum.com/Brazing-aluminum-sheet-coil-strip.html