- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

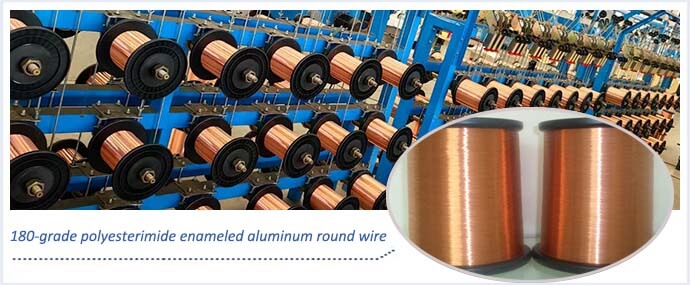

*180°C Heat Resistance | Polyesterimide Insulation | High-Purity Aluminum Core*

——Electromagnetic wire solution engineered for high-temperature, high-reliability scenarios

| Feature | Advantages of 180-class Polyesterimide Enameled Round Aluminum Wire |

| Heat Resistance | Continuous operating temperature 180°C (Class H insulation standard) |

| Insulation | Polyesterimide enamel: Chemical corrosion resistance + Wear/scratch resistance |

| Conductivity | 99.6% high-purity aluminum core, resistivity 15% below national standard |

✅ New Energy Power Systems

EV motor windings (180°C engine compartment environments)

Photovoltaic inverter transformers (resists thermal cycling shock)

✅ Critical Industrial Equipment

Class H dry-type transformers (continuous 180°C operation)

Explosion-proof electrical windings (resists chemical gas corrosion)

Note: Using standard enameled wire may increase insulation failure risk by 300%

✅1. Storage & Transportation

180-class polyesterimide enameled round aluminum wire requires:

Humidity ≤80% | Temperature 10-30°C | Light-proof & shock-resistant packaging

✅2. Key Processing Requirements

| Process | Specifications for 180-class Enameled Aluminum Wire |

| Cutting | Dedicated tools for burr-free, smooth cuts |

| Soldering | Remove enamel completely; max. 300°C/3s |

| Bending | Min. bend radius ≥2× wire diameter; zero enamel cracking |

✅3. Usage & Maintenance

Safety Limits:

Current ≤ Rated value | Ambient temperature ≤ 180°C

Monthly Checks:

Insulation resistance ≥100MΩ (megohmmeter test)

No discoloration/flaking (microscope inspection)

Extended Lifespan: 2.5× longer than Class 155 wire (180°C aging test)

Extended Lifespan: 2.5× longer than Class 155 wire (180°C aging test) Reduced Failure Rate: 40% fewer winding failures with compliant use

Reduced Failure Rate: 40% fewer winding failures with compliant use Compatibility: Works with all high-temperature connectors (crimping/soldering)

Compatibility: Works with all high-temperature connectors (crimping/soldering)

Original Source:Magnet Wires for Power Industry