- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

Why Choose 5052 Black Anodization?

► Crease-Free Bending: Magnesium-enhanced, bending coefficient as low as 0.3T (industry avg. 0.5T)

► Salt Spray Resistance: Sealed porosity <0.5% (blocks coastal chloride penetration)

► Eco-Conductive: RoHS 2.0 certified, bulk resistivity <4.5μΩ·cm

| Parameter | 0.5mm Black Anodized sheet | 0.8mm Black Anodized sheet |

| Bending Limit | 10x 180° reverse bends without cracking | Zero-failure sharp bending at R=1t (t=thickness) |

| Marine Anti-Corrosion | 2000hrs salt spray no whitening (ASTM G85) | 2500hrs salt spray, 90% blackness retention |

| Lightweight Index | Density 2.68g/cm³ (35% lighter vs steel) | 40% thickness reduction at equal strength |

| Designated Grade | 5052-H32 (High ductility + Medium strength) | 5052-H34 (Enhanced fatigue resistance) |

✅ Precision Sheet Metal Fabrication

*0.5mm Ultra-Thin sheet*:

▶ Medical device housings (Antibacterial coating, ISO 13485 certified)

▶ Drone battery compartments (15g weight reduction, 25dB EMI shielding)

✅ Marine Facility Cladding

*0.8mm Corrosion-Resistant sheet*:

▶ Cruise ship cabin panels (Resists Category 8 sea wind corrosion)

▶ Coastal curtain walls (Self-cleaning surface, ↓70% maintenance cost)

✅ Consumer Electronics Innovation

Flex Tech:

▶ Foldable phone supports (100,000-cycle bend test)

▶ Curved sports earphones (IPX8 waterproof + shock-absorbing structure)

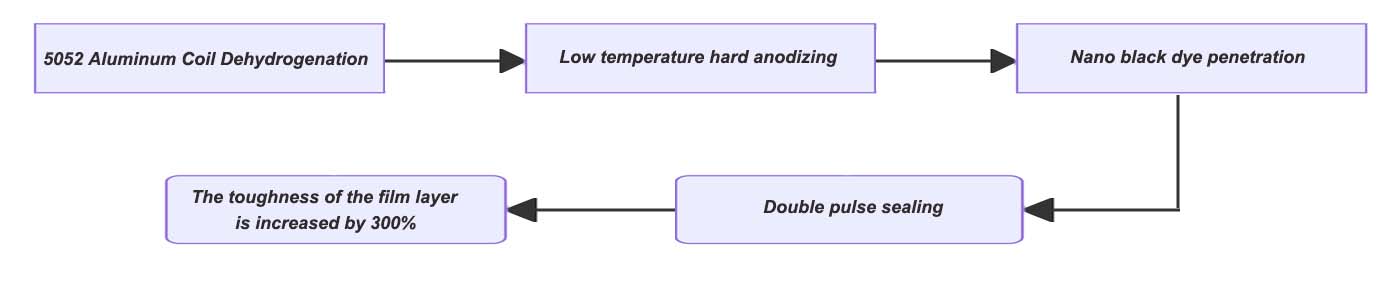

Traditional Pain Points → Coating peel at bends | Coastal whitening | Uneven conductivity

✅Our Solution:

✅Performance Breakthrough:

Bend cracking threshold >25° (conventional sheets ≤15°)

Blackness durability ΔE<1.5 (5000hrs UV test)

| Industry | Cost Advantage | Performance Gain |

| Metal Stamping | 40% lower die wear | Min. bend radius ↓0.3T |

| Marine Eng. | 60% anti-corrosion coating saved | Service life ↑30 years |

| 3C Electronics | 35% assembly efficiency increase | 100% drop test pass rate |

Original Source:Anodized Aluminum Sheet Coil