- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

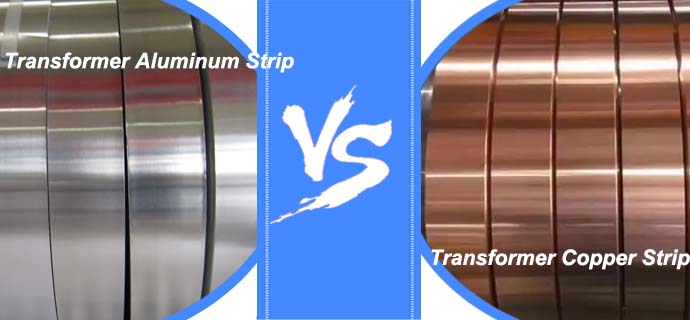

Transformer Aluminum Strip

Transformer Aluminum StripAluminum strip is a very useful and versatile material for transformers and other electrical equipment. It has light weight, high strength, excellent corrosion resistance and conductivity (ability to transmit electric current). Common alloys used for transformer aluminum strip are: 1050 aluminum strip/coil, 1060 aluminum strip/coil, 1070 aluminum strip/coil and 1350 aluminum strip/coil.

Aluminum strip/foil for transformer winding, with high conductivity, soft texture, smooth surface, no burr, no wave. The fineness of aluminum foil can be controlled at 0.2 mm or less, and the alloy composition and state can be adjusted according to customer requirements. The thickness tolerance is ±0.007 mm, the width tolerance is ±1mm, the diagonal difference is ≤1mm, and the surface quality is good.

Transformer Copper Strip

Transformer Copper StripCopper foil is one of the main materials for producing transformers. It is mainly used to connect the transformer core and the output terminal. The production process of copper strip/foil for transformer winding is to use continuous casting and rolling to produce long copper strips with a thickness of 0.2mm-1.2mm.

Transformer copper strip is made of pure copper and is used in transformers. The material is very strong and flexible, making it very suitable for use in electrical equipment. It is also easy to shape, weld and solder. Copper strip made of high-quality oxygen-free copper, has good conductivity, small contact resistance, low temperature rise, and can effectively reduce power loss and ensure long-term stable operation of the transformer.

Copper strip for transformer winding class:ETP (Electrolytic hard asphalt);T2;C11000, C12200, C26000, etc.

1. Material properties

1. Material properties

| Name | Copper Strip(Cu) | Aluminum Strip(Al) |

| Density | 8.96 g/cm³ (Heavy weight) | 2.70 g/cm³ (Light weight) |

| Conductivity | 58×10⁶ S/m (High conductivity) | 37.7×10⁶ S/m (Good conductivity) |

| Melting point | 1085°C (High temperature resistance) | 660°C (Good thermal stability) |

2. Characteristics of Aluminum and Copper Tape for Transformers

2. Characteristics of Aluminum and Copper Tape for Transformers

Aluminum tape is more corrosion and heat resistant than copper tape, which makes it suitable for outdoor use.

The electrical conductivity of aluminum is lower than copper at room temperature, but increases with increasing temperature. This means that aluminum is more efficient than copper in transferring heat, making it ideal for electric heating elements and radiators.

Copper can be recycled many times without losing its properties, while aluminum loses strength after many recycling cycles. Copper can be recycled indefinitely if there is no contamination in the mix; however, pure aluminum easily corrodes when exposed to oxygen or water vapor in the air environment during the melting process and therefore cannot be recycled.

3. Cost of Aluminum and Copper Tape for Transformers

3. Cost of Aluminum and Copper Tape for TransformersAluminum tape is relatively cheaper than copper tape.

4. Density of Aluminum and Copper Tape for Transformers

4. Density of Aluminum and Copper Tape for TransformersThe specific gravity of copper is 8.9 and that of aluminum is 2.7.

The density of a substance is the ratio of its mass to its volume. Density is a measure of how compact or bulky a substance is. The difference in density between aluminum and copper can be used to determine how much material is needed for an application that uses aluminum instead of copper.

5. Conductivity of aluminum and copper strips for transformers

5. Conductivity of aluminum and copper strips for transformersAluminum strips have a conductivity of 60% IACS or more.

Copper strips have a conductivity of 99.80% IACS.

The resistivity of a material is a measure of its resistance to the flow of electric current. This property is important for transformers because it determines how much heat a material can withstand before melting or burning. The higher the resistivity, the more heat it can dissipate without reaching unsafe temperatures.

| Alloy | Al (%) | Si (%) | Fe (%) | Cu (%) | Mn (%) | Zn (%) | Mg (%) | Ti (%) | Other elements (%) |

| MIN | Max | Max | Max | Max | Max | Max | Max | ||

| 1050 | 99.5 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 0.03 |

| 1060 | 99.6 | 0.25 | 0.35 | 0.05 | 0.03 | 0.05 | 0.03 | 0.03 | 0.03 |

| 1070 | 99.7 | 0.25 | 0.04 | 0.03 | 0.04 | 0.04 | 0.03 | – | 0.03 |

| 1350 | 99.5 | 0.1 | 0.05 | 0.01 | 0.01 | – | – | – | 0.03 |

| C1100/C11000 chemical composition of copper strip (%) | ||||||||

| Element | Cu+Ag | Sn | Zn | Pb | Ni | Fe | As | O |

| Standard | ≥99.90 | ≤0.002 | ≤0.005 | ≤0.005 | ≤0.005 | ≤0.005 | ≤0.002 | ≤0.06 |

Original Source:Transformer Aluminum Strip