- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

Colored Aluminum Coil is the core material for modern building curtain walls, industrial equipment and decoration projects. Its quality directly affects the project cost and service life. This article combines international standards such as ASTM and AAMA to analyze the selection guide for colored aluminum coils to help you avoid procurement risks.

✅ Architectural curtain wall projects: PVDF Coated Aluminum Coil is preferred, with strong weather resistance and color retention of more than 20 years;Thickness recommendation: 0.3-4.0mm for exterior walls, and the thickness of load-bearing parts must be ≥2.5mm

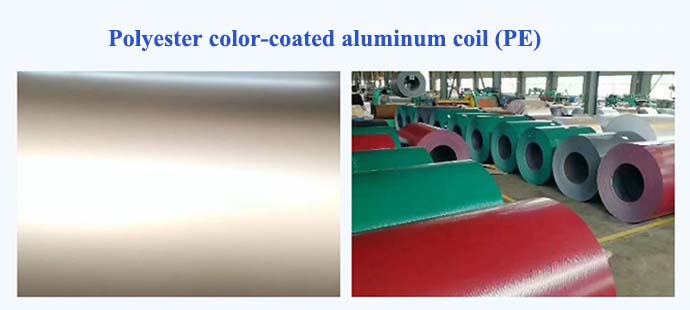

✅Industrial equipment protection: PE Coated Aluminum Coil is selected, which is cost-effective and scratch-resistant;Surface hardness must reach 3H or above (pencil hardness test).

✅Wood Grain Aluminum Coil is recommended for interior decoration, and the fire protection level must reach A2 level.

1. Substrate quality

1. Substrate qualityAlloy grade: 1060 3003 aluminum coil (general use), 5052 5754 aluminum coil (high corrosion resistance scenario)

Tensile strength: Curtain wall projects require ≥150MPa (refer to GB/T 3880 standard)

2. Coating system

2. Coating systemComparison of coating types:

| Coating | Use life | UV resistance | Applicable scenarios |

| PVDF | 20-30 years | ★★★★★ | Coastal/highly polluted areas |

| PE | 10-15 years | ★★★☆ | General outdoor projects |

| HDPE | 5-8 years | ★★☆ | Temporary facilities |

3. Thickness tolerance

3. Thickness toleranceIndustry allowable deviation: ±0.02mm

Quality documents

Quality documents◆ The substrate must be accompanied by ISO 9001 production certification

◆ The coating must provide an SGS heavy metal content test report

Performance testing

Performance testing◆ Salt spray test ≥3000 hours (ASTM B117 standard)

◆ Color difference ΔE≤1.5 (CIE Lab system measurement)

✅ Bulk purchase: 5%-12% discount for a single order of more than 20 tons

✅ Futures lock-in: It is recommended to sign an LME hedging contract during the period of aluminum ingot price fluctuations

✅ Logistics optimization: Choose suppliers with longitudinal shearing and slitting services to reduce secondary processing losses

Mastering the key points of colored aluminum coil selection can save 15%-30% of the project budget. It is recommended to first request samples for bending test (T bend ≤ 2T) and adhesion test (cross-cut method up to level 0), and regularly check the supplier’s AMS 3094 process certification. Flait Aluminum is a professional Colored Aluminum Coil supplier, contact us to get a customized material selection plan! Click to Order

Original Source:Color coated aluminum coil