- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

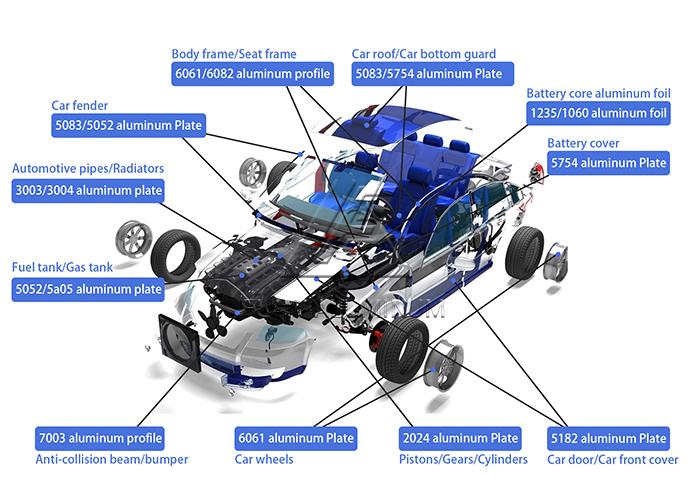

With the continuous development of automotive manufacturing technology and the increasing environmental awareness, automotive aluminum alloys have been widely used in the automotive industry as lightweight and high-strength materials. This article will introduce several common aluminum alloy grades and their specific applications in automotive manufacturing, as well as discuss the advantages of Automotive aluminum alloys in this field.Click to Order

5xxx Series Automotive aluminum alloys:

Example alloys: 5052, 5754, 5182, etc.

Applications:

Body panels: 5xxx series automotive aluminum alloys have excellent corrosion resistance and weldability, making them suitable for manufacturing automotive body panels such as outer shells, doors, and engine hoods.

Fuel tanks: Aluminum alloy fuel tanks reduce the overall weight of the vehicle, improving fuel efficiency and overall performance.

6xxx Series Automotive aluminum alloys:

Example alloys: 6061, 6063, etc.

Applications:

Structural components: 6xxx series Automotive aluminum alloys offer high strength and good processability, commonly used in the production of automotive chassis and body structural components such as suspension systems, wheels, and frames.

Radiators: Aluminum alloy radiators improve the heat dissipation efficiency of vehicles, helping to maintain the normal operating temperature of engines and other critical components.

7xxx Series Automotive aluminum alloys:

Example alloys: 7075, 7050, etc.

Applications:

Wheels: 7xxx series Automotive aluminum alloys possess extremely high strength and excellent fatigue performance, making them ideal for manufacturing high-performance vehicle wheels, enhancing handling and driving comfort.

Lightweight: Automotive aluminum alloys are lighter than traditional steel, reducing the overall weight of vehicles and improving fuel efficiency and power performance.

Lightweight: Automotive aluminum alloys are lighter than traditional steel, reducing the overall weight of vehicles and improving fuel efficiency and power performance. High strength: Despite their lightweight nature, automotive aluminum alloys can achieve or even exceed the strength of certain steel materials, providing sufficient structural strength and safety for Automotives.

High strength: Despite their lightweight nature, automotive aluminum alloys can achieve or even exceed the strength of certain steel materials, providing sufficient structural strength and safety for Automotives. Excellent corrosion resistance: Automotive aluminum alloys exhibit excellent resistance to oxidation, corrosion, and humidity, enhancing the durability of vehicles.

Excellent corrosion resistance: Automotive aluminum alloys exhibit excellent resistance to oxidation, corrosion, and humidity, enhancing the durability of vehicles. Processability: Automotive aluminum alloys are easily processed and formed, meeting the complex shapes and design requirements in automotive manufacturing.

Processability: Automotive aluminum alloys are easily processed and formed, meeting the complex shapes and design requirements in automotive manufacturing. Recyclability: Automotive aluminum alloys are recyclable materials, contributing to environmental sustainability and reducing waste of resources.

Recyclability: Automotive aluminum alloys are recyclable materials, contributing to environmental sustainability and reducing waste of resources.Automotive aluminum alloys play a crucial role in automotive manufacturing. By utilizing different grades of Automotive aluminum alloys, various requirements for components such as body panels, structural parts, and wheels can be met. The advantages of Automotive aluminum alloys, including lightweight construction, high strength, corrosion resistance, and processability, contribute to improved performance and environmental friendliness in automotive manufacturing. As technology continues to advance, the application of Automotive aluminum alloys in the automotive industry will further expand, driving the industry towards greater efficiency and sustainability.

Original Source: Automobile Aluminum Sheet Plate