- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

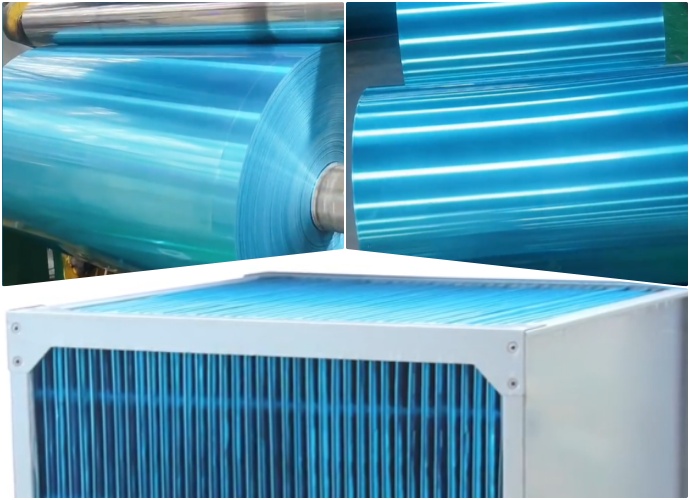

Product name: Hydrophilic aluminum foil

Alloys: 8011/1100/3102/1030b

Tempers: O/HO, H22, H24, H26

Thickness: 0.08-0.20mm (Tolerance: +/-5%)

Width: 100-1250mm (Tolerance: +/-1.0mm)

Coil ID: 75mm, 150mm, 300mm, 400mm, 500mm

Coil sleeve: Aluminum/carbon/steel

Surface color: Blue, gold/golden, bare

Standards: EN, ASTM, DIN, GB/T-3198

Delivery time: 25-30 days

Payment terms: T/T, L/C at sight.

Package: Waterproof paper and plastic cover the package, and then make the wooden pallet.

Application: Air conditioner, heat exchanger, evaporator, etc.

Remark: Customized production is available, contact us for free samples.

Hydrophilic aluminum foil for air conditioning is one of our company’s main products. Hydrophilic aluminum foil is a deep-processed product of aluminum foil for fin stock heat exchangers. It is made by coating an air-conditioning aluminum foil with a thickness of about 0.1mm with an anti-corrosion coating and a hydrophilic coating, and drying it in a drying oven, can effectively prevent defects such as oxidation, water bridges, white powder blowing, and growth of aluminum foil during use. It can also reduce wind resistance, reduce the operating noise of the air conditioner, and ensure the long-term and stable heat exchange effect of the air conditioner.

8011 hydrophilic aluminum foil is widely used in refrigeration equipment, such as air conditioners, heat exchangers, condensers, coolers, evaporators and other fields. The use of 8011 hydrophilic aluminum foil for air conditioners is mainly used to make heat-conducting fins for air conditioner heat exchangers. The common tempers are H22/H24/H26, and the thickness range is 0.08-0.2mm. Blue & Gold Hydrophilic Aluminum Foil is a common material used for hydrophilic aluminum fins. The performance of 8011 hydrophilic aluminum foil is better than pure aluminum foil. The surface is clean, the color is uniform, and there are no spots and holes. It can be customized and produced according to customer needs.

1. Plate shape of hydrophilic aluminum foil: The production process of hydrophilic aluminum foil requires the aluminum foil to have a good plate shape, which is a prerequisite for the production of coated aluminum foil, because only a good plate shape is the basis for uniform coating. The unit of measurement for shape index is I. Flat type general coating production equipment requirements are within 20-40I. If it is larger than this value, a tension straightening system needs to be added before the coating equipment.

2. Coating performance: Hydrophilicity is simply the affinity between the aluminum foil surface and water, measured by the angle formed by water droplets on the aluminum foil surface. The angle of water droplets on the surface of ordinary aluminum foil is above 70 degrees, and the angle of water droplets on the surface of hydrophilic aluminum foil is below 35 degrees. Fins with good hydrophilicity can improve the heat exchange efficiency of the air conditioner heat exchanger, significantly save power consumption, and effectively reduce the spacing between the heat exchanger fins, thereby reducing the size of the air conditioner, and thus achieving beautify the appearance of the air conditioner and improve room space utilization for household air conditioners.

3. Coating thickness: The coating thickness on the surface of aluminum foil is usually less than 3/1m. The thickness of the coating directly affects the performance indicators of the coating, so the coating thickness on the surface of the aluminum foil must be uniform.

4. Coating adhesion: The adhesion of the coating is an indicator of the adhesion fastness of the aluminum foil to its surface coating. If the coating adhesion is too small, the surface coating will easily fall off during further processing and use of the coated aluminum foil, seriously affecting the weight of the coated aluminum foil. Therefore, the stronger the adhesion of the coating, the better the effect.

5. Hydrophilicity: After a period of use, hydrophilic aluminum foil will be affected by various environmental factors, which will affect the hydrophilicity of the surface. Therefore, hydrophilicity is usually divided into initialhydrophilicity and hydrophilicity after environmental resistance testing. The quality of hydrophilicity is mainly measured by the angle size of a. Generally, the initial hydrophilicity requirement of a product is a<100, and the hydrophilicity requirement after environmental resistance test is a<250. The contact angle can be measured using a special contact angle measuring instrument; it can also be calculated by the size of the area occupied by a certain volume of water droplets on the surface of the aluminum foil.

6. Corrosion resistance: Corrosion resistance is mainly reflected in three aspects: First, alkali resistance. Since the lubricating oil on the surface of the heat exchange fin needs to be removed with an alkaline cleaning agent after being punched, the functional coating on the surface of the aluminum foil must have a certain degree of alkali resistance, it is generally required to be immersed in 20% NaOH solution for 3 minutes without bubbling; the second is salt spray corrosion resistance. Generally, the test conditions are 35°C and 3% salt water spray environment, and there are no corrosion spots for 500 hours. The resistance to salt spray corrosion is directly related to the service life of the heat exchanger. In coastal areas, due to the high salt content in the air, there are higher requirements for the salt spray corrosion resistance of the heat exchanger; the third is heat and humidity resistance, that is, corrosion resistance when placed under a certain temperature and humidity for a long time. This performance is also an important indicator of the weather resistance of the heat exchanger.

Original Source:https://www.flait-aluminum.com/Hydrophilic-Aluminum-Foil-For-Air-Conditioner-Heat-Exchanger.html

Tags:8011 aluminum foil