- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

The heat exchanger is one of the key components of the air conditioner, mainly used to achieve heat exchange between indoor air and the refrigerant in the air conditioning system pipeline. Air conditioning aluminum foil is a special material for manufacturing heat exchanger fins for air conditioners.

The commonly used materials of air conditioning aluminum foil are 1100 aluminum foil, 3003 aluminum foil, 8011 aluminum foil, 8006 aluminum foil, commonly used tempers are O/HO, H22, H24, H26, thickness range 0.09-0.20mm, width range 100-1300mm, tube core inner diameter 76mm/150mm air conditioning aluminum foil is widely used in air conditioning heat exchange equipment, with good plate shape, good coating performance, high coating adhesion, good hydrophilicity, good corrosion resistance and other advantages.

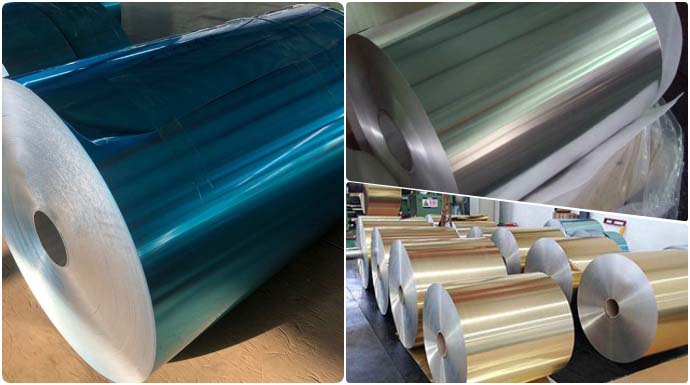

✅1. Plain/bare aluminum, which is the color of pure aluminum

✅2. Hydrophilic aluminum, which has a green coating on the surface, which can be further divided into blue, light color, etc.

✅3. Gold aluminum and black aluminum foil, which also has a black or gold coating on the surface.

The choice of air-conditioning aluminum foil color should be based on material characteristics, use environment and functional requirements.

* Blue hydrophilic air conditioning aluminum foil

* Blue hydrophilic air conditioning aluminum foilMaterial: hydrophilic aluminum foil (surface coated with hydrophilic coating).

Use: ordinary household air conditioners, suitable for scenes that pursue energy saving and stability.

Advantages: good hydrophilic performance, water drop contact angle ≤35°, condensed water flows away quickly, reducing the “water bridge” phenomenon, and increasing heat exchange efficiency by about 5%.

* Gold/Black hydrophilic air conditioning aluminum foil

* Gold/Black hydrophilic air conditioning aluminum foilMaterial: corrosion-resistant hydrophilic aluminum foil (coating contains anti-corrosion ingredients).

Use: outdoor units or special climate areas, high humidity and high salt areas (such as the seaside).

Advantages: strong corrosion resistance, which can extend the life of the fins. For example, the corrosion resistance of the gold fins has been increased from 500 hours to 1,000 hours, making them suitable for high humidity and high salt environments (such as the seaside)

* Plain/bare air conditioning aluminum foil

* Plain/bare air conditioning aluminum foilMaterial: non-coated aluminum foil (rolling annealing only)

Use: scenarios with limited budgets or low performance requirements

Disadvantages: Only rolled annealing treatment, no hydrophilic or anti-corrosion coating, easy to oxidize and discolor, and heat exchange efficiency decreases after long-term use.

| Alloy Series | Alloys | Tempers | Thickness (mm) | Width (mm) | Length (mm) |

| 1 Series | 1100 | O、H14、H16、H22、H26、H24,, etc. | 0.014-0.20 | 20-1600 | C |

| 3 Series | 3003 | ||||

| 8 Series | 8011, 8006 |

1. Improve heat exchange efficiency

1. Improve heat exchange efficiencyAccelerate the discharge of condensed water: The hydrophilic coating reduces the surface tension of condensed water, allowing the water film to spread and flow away quickly, reducing the “water bridge” phenomenon, avoiding air flow obstruction, and improving the heat exchange efficiency by 10%~15%.

Reduce thermal resistance: By reducing the retention of condensed water on the surface of the aluminum foil, the thermal resistance of the water film is reduced and the heat exchange rate is improved.

2. Energy saving and environmental protection

2. Energy saving and environmental protectionReduce energy consumption: The efficient heat exchange capacity makes the air conditioner consume less energy under the same cooling effect, indirectly reducing carbon emissions.

Environmentally friendly materials: Some coatings use non-toxic, fluoride-free environmentally friendly processes that meet modern environmental standards.

3. Extend service life

3. Extend service lifeReduce scale deposition: The hydrophilic coating inhibits the adhesion of scale and dirt, reduces maintenance frequency, and extends the service life of the aluminum foil.

Anti-corrosion protection: Some coatings contain anti-corrosion ingredients that can slow down the corrosion of aluminum foil by salt spray or humid environments.

4. Improve air quality

4. Improve air qualityAntibacterial and antibacterial: Some hydrophilic coatings add antibacterial groups (such as nanosilver), which have an antibacterial rate of more than 99% against common bacteria such as Escherichia coli and Staphylococcus aureus, inhibiting the reproduction of microorganisms.

Reduce odor: The hydrophilic property prevents long-term retention of water, inhibits the growth of mold, and maintains fresh indoor air.

5. Structural optimization and noise reduction

5. Structural optimization and noise reductionCorrugated fin design: Combined with the hydrophilic coating, it accelerates the discharge of condensed water, reduces frosting and blockage, and improves heating performance.

Reduce operating noise: Rapid drainage reduces the noise generated by the collision of water droplets and fins, and optimizes user experience.

Original Source:Hydrophilic Aluminum Foil For Air Conditioner Heat Exchanger