- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

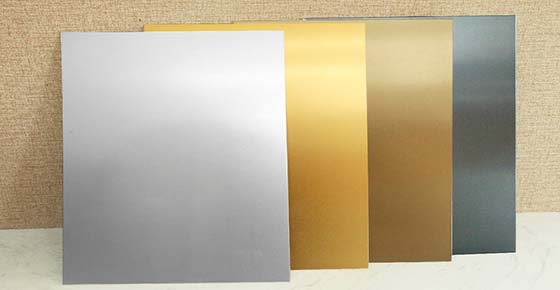

Anodizing is a metal surface treatment process. After anodizing, the surface hardness, wear resistance, high temperature resistance and corrosion resistance of the aluminum plate will be enhanced, and its appearance will be more high-end and more decorative. The original surface treatment process of aluminum plates determines that anodized aluminum plates have different finishes. This article introduces three types of anodized aluminum plates with different finishes, namely satin anodized aluminum plates, brushed anodized aluminum plates and mirror anodized aluminum plates.

Satin anodized aluminum plate refers to an anodized aluminum plate with a satin texture on the surface. The satin effect is achieved by controlling parameters such as temperature, concentration, voltage and time of the electrolyte during the oxidation process. By controlling the parameters, satin-finished alumina plates of different colors can be obtained. Among them, the aluminum natural color satin oxide aluminum plate is the most popular color. In addition, champagne gold, gray, bronze, black and other colors can also be customized.

Satin anodized aluminum plates not only have a high-end metal appearance and texture, but also have stronger hardness, wear resistance, corrosion resistance and durability than aluminum plates. They are often used in high-end hotels, office buildings, shopping malls, conference halls, exhibition halls, stations and other construction sites.

Brushed anodized aluminum plate refers to an anodized aluminum plate whose surface has been treated by drawing process. The order of the two is drawing first and then anodizing.

The brushed anodized aluminum plate not only improves the wear resistance and weather resistance of the aluminum plate, but also further enhances the decorative nature of the aluminum plate, making it more fashionable and technological.

Brushed anodized aluminum panels are mainly used in indoor and outdoor curtain walls, partitions, ceilings and other decorations.

Mirror anodized aluminum plate refers to an anodized aluminum plate with a mirror effect on its surface. The sequence is to first perform mirror processing on the aluminum plate, and then perform anodizing processing.

The aluminum plate has a mirror effect after grinding, polishing, rolling and other processes. The surface is smooth and high-gloss. Surface oxidation treatment can improve the scratch resistance and weather resistance of the aluminum plate. It is often used as a high-end decorative material.

Mirror aluminum oxide plates can show excellent mirror effects without the shortcomings of fragile and difficult-to-clean mirrors. They also have the advantages of light weight, moisture-proof and fire-proof, self-cleaning, weather resistance, and corrosion resistance. They can be used in extreme environments. It also ensures a long service life.

Original Source:https://www.flait-aluminum.com/Anodized-Aluminum-Sheet-Coil.html