- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

As the automotive manufacturing industry moves toward lightweighting, electrification, and sustainability, aluminum alloys have become a key material in achieving these goals. Their excellent strength-to-weight ratio, outstanding corrosion resistance, and superior recyclability make them highly favored for applications such as body structures, chassis, powertrains, and battery systems. However, with numerous aluminum alloy grades available, selecting the most suitable one has become a significant challenge. This article provides a practical guide to material selection.

Aluminum alloys commonly used in the automotive industry can be divided into the following series, each with unique performance characteristics:

✅ 5xxx Series (Al-Mg)

🔹Characteristics: Excellent corrosion resistance and weldability, moderate strength, good formability

🔹Typical Grades: 5754, 5182, 5052

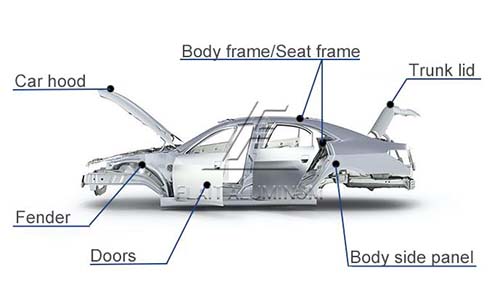

🔹Automotive Applications: Body panels such as doors, hoods, and trunk lids; body structural components

✅ 6xxx Series (Al-Mg-Si)

🔹Characteristics: Good balance of strength, formability, and corrosion resistance; can be strengthened through heat treatment

🔹Typical Grades: 6061, 6063, 6082

🔹Automotive Applications: Body panels, structural components, anti-collision beams, battery enclosures

✅ 7xxx Series (Al-Zn-Mg)

🔹Characteristics: Ultra-high strength, but relatively poor corrosion resistance; usually requires coating protection

🔹Typical Grades: 7020, 7075

🔹Automotive Applications: Safety structural components, anti-collision systems, suspension parts

◆ 1. Performance Requirements

Strength needs: Determine the required strength grade based on the load-bearing requirements of the component

Formability requirements: Deep-drawn parts require materials with high formability

Corrosion resistance: Components exposed to harsh environments require higher corrosion resistance

Weldability: Parts that need welding should select grades suitable for welding

◆ 2. Manufacturing Process

Stamping: Choose grades with good formability, such as 5xxx and 6xxx series

Extrusion: Suitable for 6xxx series alloys

Casting process: Select cast aluminum alloys with good fluidity

◆ 3. Cost-Effectiveness

Material cost: Significant price differences exist among different grades

Processing cost: Easily processable materials can reduce manufacturing costs

Lifecycle cost: Consider durability and maintenance costs

◆ 4. Lightweighting Goals

Specific strength: Evaluate strength performance per unit weight

Component integration: Reduce the number of parts through design optimization

Body Panels: Aluminum sheet 5754 offers good formability and surface quality, making it suitable for appearance parts such as hoods, doors, and trunk lids.

Body Panels: Aluminum sheet 5754 offers good formability and surface quality, making it suitable for appearance parts such as hoods, doors, and trunk lids. Structural Components: Aluminum sheet 6061 and aluminum sheet 6082 provide high strength and good weldability, making them suitable for seat frames, instrument panel brackets, and body skeletons.

Structural Components: Aluminum sheet 6061 and aluminum sheet 6082 provide high strength and good weldability, making them suitable for seat frames, instrument panel brackets, and body skeletons. Chassis Systems: Aluminum sheet 7020 offers high strength, making it suitable for suspension components and anti-collision structures, providing excellent impact resistance.

Chassis Systems: Aluminum sheet 7020 offers high strength, making it suitable for suspension components and anti-collision structures, providing excellent impact resistance. Battery Systems: Aluminum sheets 6061 and 5052 offer good strength and corrosion resistance, making them suitable for battery enclosures and brackets.

Battery Systems: Aluminum sheets 6061 and 5052 offer good strength and corrosion resistance, making them suitable for battery enclosures and brackets. Thermal Management Systems: Aluminum sheets 3003 and 4343 offer excellent thermal conductivity, making them suitable for radiators and heat exchangers.

Thermal Management Systems: Aluminum sheets 3003 and 4343 offer excellent thermal conductivity, making them suitable for radiators and heat exchangers.

Selecting the most suitable aluminum alloy grade requires comprehensive consideration of performance requirements, manufacturing processes, cost objectives, and sustainability, among other factors. Close collaboration with material suppliers and thorough testing and validation are key to ensuring successful selection. The right material choice not only achieves lightweighting goals but also enhances vehicle performance, safety, and environmental friendliness, creating long-term value for automotive manufacturing enterprises.Contact us for professional aluminum alloy technical support.Click to Order

Original Source:Automobile Aluminum Sheet Plate