- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

In the design and manufacturing of transformers, the choice of aluminum strip grade directly determines the product’s efficiency, reliability, and total cost. Faced with various grades like 1050, 1060, 1070, and 1350, how should engineers and procurement personnel make a decision? This article will delve into the key performance indicators and, combined with specific grades, assist you in making the optimal choice.

The selection of the transformer aluminum strip grade, as the core conductive material, is by no means a simple either/or choice but a comprehensive decision-making process that balances conductivity, mechanical strength, workability, and cost. The selection is not a simple “pick one out of four” but rather a precise match based on scientific data.

✅Similarities: These four grades belong to the category of industrial pure aluminum or high-purity aluminum, possessing excellent electrical conductivity, thermal conductivity, corrosion resistance, and workability, making them very suitable as winding materials for transformers.

✅Fundamental Differences: The core difference lies in the aluminum purity and the control of specific impurities (especially iron and silicon). Higher aluminum purity and lower impurity content result in better electrical conductivity. This seemingly minor compositional difference can be amplified into significant performance and economic gaps in large transformers or applications highly sensitive to efficiency.

| Grade | Al Content (%) (Min) | Typical Conductivity (%IACS) | Core Characteristics & Positioning | Relative Cost |

| 1050 | 99.5 | Approx. 61.0 | Economical & General-Purpose: Good overall performance, significant cost advantage. | Lowest |

| 1060 | 99.6 | Approx. 61.0 – 61.5 | Balanced Choice: Purity and conductivity slightly better than 1050, a cost-effective option. | Lower |

| 1070 | 99.7 | Approx. 61.5 – 62.0 | High Conductivity Type: Higher purity delivers superior conductivity, a key tool for high efficiency. | Higher |

| 1350 | 99.5 | Approx. 61.0 (Per Electrical Standard Control) | Electrical Standard Type: Optimized control of impurity composition ensures stable electrical performance, complies with international standards. | Medium |

1. 1070 Aluminum Strip: Efficiency Pioneer

1. 1070 Aluminum Strip: Efficiency PioneerCore Positioning: Among these four grades, the 1070 transformer aluminum strip has the highest aluminum purity (99.7%), meaning its electrical conductivity is the most outstanding.

Applicable Scenarios: When your design goal is to achieve the highest efficiency or strive to minimize transformer load loss, the 1070 is the undisputed. It is widely used in fields such as new energy and high-end power transformers.

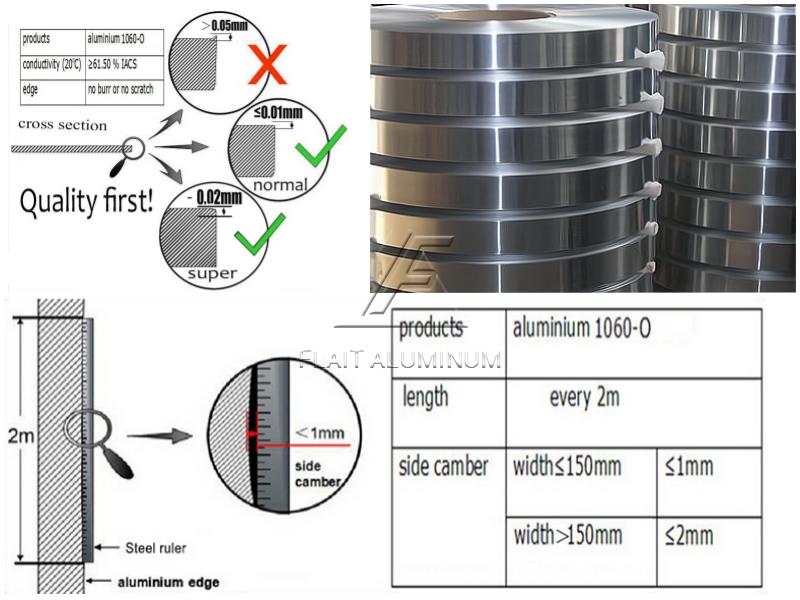

2. 1060 Aluminum Strip: King of Cost-Effectiveness

2. 1060 Aluminum Strip: King of Cost-EffectivenessCore Positioning: It achieves an excellent balance between performance and cost. Its conductivity is very close to 1070, but the cost is more advantageous.

Applicable Scenarios: The ideal choice for the vast majority of general-purpose oil-immersed and dry-type transformers. When you do not need to pursue ultimate conductivity but highly value the overall cost-effectiveness of the project, the 1060 transformer aluminum strip is a reliable and economical choice validated by the market over the long term.

3. 1350 Aluminum Strip: Practitioner of International Standards

3. 1350 Aluminum Strip: Practitioner of International StandardsCore Positioning: Although the aluminum content is the same as 1050, 1350 is an electrical grade aluminum produced strictly in accordance with the ASTM B series standards. It imposes stricter limits on impurities like iron and silicon that affect conductivity, ensuring stable electrical performance.

Applicable Scenarios: Mainly used for export products or transformers designed and manufactured strictly in accordance with international standards (e.g., IEC, IEEE). When your customer or project specifications explicitly require the use of “Electrical Aluminum” or the “1350 grade,” it is the standard answer.

4. 1050 Aluminum Strip: Reliable and Economical Pragmatist

4. 1050 Aluminum Strip: Reliable and Economical PragmatistCore Positioning: As a basic industrial pure aluminum, it provides reliable conductivity and formability while offering the greatest cost advantage.

Applicable Scenarios: Suitable for some ordinary transformers, small transformers where efficiency and loss requirements are not the most stringent, or for use as other structural components. In projects extremely sensitive to cost and where performance is sufficient, it is a viable option.

Please refer to the following paths based on your primary objective to make the final choice:

✅ Goal: Build an efficiency benchmark with the lowest losses.

🔹Decision: Choose 1070 aluminum strip. The performance premium it provides for your product will far outweigh the incremental material cost.

✅ Goal: Manufacture general-purpose transformers, seeking the best cost-effectiveness.

🔹Decision: 1060 aluminum strip is your “gold standard.” Its balance between performance and cost is almost impeccable.

✅ Goal: Meet international standards and produce equipment for export.

🔹Decision: Confirm the specifications; usually, the 1350 aluminum strip is the correct choice that meets the requirements and avoids compliance risks.

✅ Goal: Extremely limited budget, and performance requirements are lenient.

🔹Decision: 1050 aluminum strip can be considered, but the total cost of long-term operating energy consumption should be carefully evaluated.

Original Source:Transformer Aluminum Strip