- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

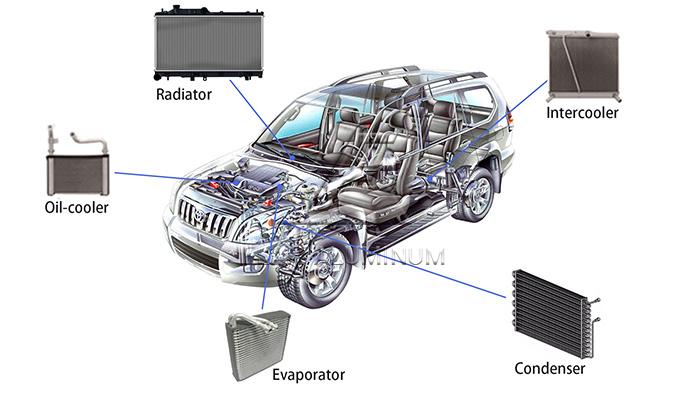

In today’s automotive industry, which is rapidly advancing toward electrification and efficiency, innovation in every component is critical. The performance of automotive heat exchangers (such as battery cooling plates, radiators, condensers, and evaporators) directly determines a vehicle’s range, safety, and efficiency. As a core material expert in this field, Flait Aluminum is committed to providing world-leading automotive brazed aluminum sheets and a full range of aluminum alloy grades to support your design and manufacturing.

As vehicle lightweighting becomes an irreversible trend, aluminum alloys have largely replaced traditional copper materials due to their excellent strength-to-weight ratio. The brazing process, as an efficient and reliable joining technology, allows for the welding of complex multi-layer structures in a single step, significantly improving production efficiency and product consistency. Flait Aluminum’s brazed aluminum sheets are specifically designed for this advanced process.

We provide a full range of clad aluminum sheets that comply with ASTM, EN, GB, and JIS standards to meet your needs for various application scenarios.

Excellent Brazing Performance and Flowability

Excellent Brazing Performance and FlowabilityCladding Alloy Grades: We offer multiple brazing filler options, including 4343 (AISi7.5), 4045 (AISi10), and the low-silicon environmentally friendly formula 4070 (AISi2). These alloys feature stable melting points, excellent flowability, and filling capability, enabling the formation of smooth, full welds. This ensures unimpeded flow in every channel of the heat exchanger, fundamentally eliminating leakage risks.

Outstanding Strength, Formability, and Corrosion Resistance

Outstanding Strength, Formability, and Corrosion ResistanceCore Alloy Grades: Our most commonly used high-performance core material is 3003 (Al-Mn) alloy, which maintains excellent strength and good deep-drawing performance after brazing, making it an ideal choice for components like radiators and condensers. For parts requiring higher strength, we provide alloys such as 6951 (Al-Mg-Si), which can significantly increase in strength through aging treatment after brazing.

Cladding for Corrosion Protection: To enhance overall corrosion resistance, we can add 7072 (Al-Zn) alloy as an anodic protective layer on one or both sides of the clad sheet. This material effectively resists erosion from coolant, refrigerant, and atmospheric environments, significantly extending the product’s service life.

Tailored for New Energy Vehicle Battery Cooling Plates

Tailored for New Energy Vehicle Battery Cooling PlatesFor Electric Vehicle (EV) battery cooling plates, we recommend the classic combination of a 3003 core with a 4045 or 4343 cladding layer. This combination offers high thermal conductivity, excellent brazing sealability, and good corrosion resistance, making it a key material for ensuring battery safety and improving driving range.

✅ New Energy Vehicle Battery Cooling Plates: Core 3003 + Cladding 4045/4343

✅ Engine Radiators & Intercoolers: Core 3003 + Cladding 4045/4343 + 7072 Clad Layer

✅ Air Conditioning System Condensers & Evaporators: Core 3003 + Cladding 4070/4045

✅ Oil Coolers & EGR Coolers: Core 6951/3003 + Cladding 4045

🔹Strict Quality Control: From melting and casting to rolling, we implement the IATF 16949 quality management system throughout the entire process to ensure stable performance and precise dimensions for every coil.

🔹Professional Technical Support: Our team of experienced engineers provides comprehensive technical support and solutions, from grade selection and brazing process parameters to mold design.

🔹Stable Supply Chain & Customization Services: Strong production capacity ensures timely delivery. We also offer customized production services for non-standard grades and specifications.

Contact Flait Aluminum’s expert team now for free samples and technical documentation! Click to Order

Original Source:Brazing Aluminum Sheet Coil Strip