- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

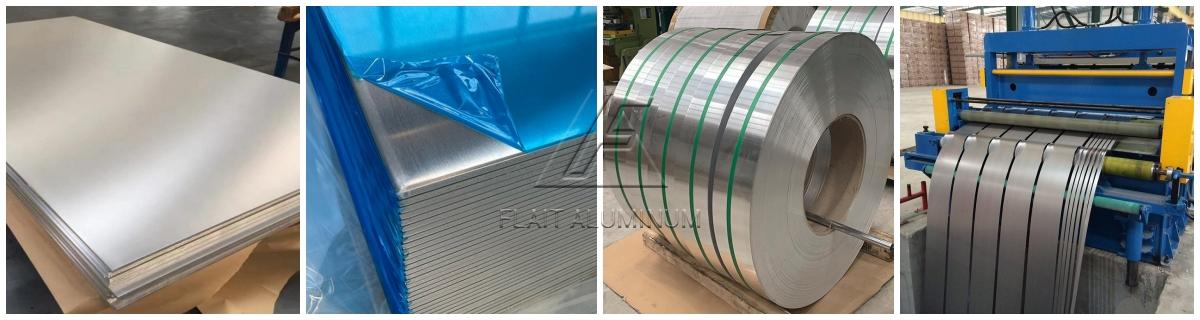

5052 Aluminum plate strip belongs to the Al-Mg series alloy, is used in a wide range of applications, especially is the construction industry. The main alloy element of 5052 aluminum plate strip is magnesium. It has high strength, especially fatigue resistance, high plasticity and corrosion resistance. It cannot be strengthened by heat treatment; during semi-cold work hardening, the plasticity is still good; during cold work hardening, has low plasticity, good corrosion resistance, good weldability, poor machinability, and it can be polished. 5052 aluminum plate strip are mainly used for low-load parts that require high plasticity and good weldability and work in liquid or gas media, such as food processing equipment, trucks, trailers and transport parts, marine parts, boats, pontoons and docks, tanks and pressure vessels, electronic chassis, aircraft, architecture, cabinets. Flait Aluminum provides 5052 thin aluminum plate, 5052 medium and thick aluminum plate, 5052 thick aluminum plate, 5052 checkered aluminum plate; common tempers are 5052-O, 5052-H112, 5052-H32, 5052-H34.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Other | Al | ||

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.20-2.80 | 0.15-0.35 | – | 0.1 | – | – | Single | Total | Remainder | |

| 0.05 | 0.15 | |||||||||||||

| Alloy | Temper | Thickness(mm) | Tensile strengthRm(Mpa) | Yield strengthRp0.2(MPa) | ElongationA(%) | Hardness HBWa |

| 5052 | O/H111 | 0.20-0.50 | 170-215 | ≥65 | 12 | 47 |

| 0.50-1.50 | 14 | 47 | ||||

| 1.50-3.00 | 16 | 47 | ||||

| 3.00-6.00 | 18 | 47 | ||||

| 6.00-12.50 | 165-215 | 19 | 46 | |||

| H32 | 0.20-0.50 | 210-260 | ≥130 | 5 | 61 | |

| 0.50-1.50 | 6 | |||||

| 1.50-3.00 | 7 | |||||

| 3.00-6.00 | 10 | |||||

| 6.00-12.50 | 12 | |||||

| H34 | 0.20-0.50 | 230-280 | ≥150 | 4 | 67 | |

| 0.50-1.50 | 5 | |||||

| 1.50-3.00 | 6 | |||||

| 3.00-6.00 | 7 | |||||

| 6.00-12.50 | 9 |

Tensile strength (σb) : 170~305MPa

Conditional yield strength σ0.2 (MPa) ≥ 65

Elastic Modulus (E): 69.3 to 70.7 Gpa

Annealing temperature: 345°C.

| Alloy | Thermal expansion coefficient(20-100℃) µm/m•kRm/Mpa | Melting point range(℃)Rp0.2/Mpa | Conductivity 20℃(68°F)(%IACS) | Resistivity 20(68°F)Ωmm2/m | Density(20℃)(g/cm³) |

| 5052-H32 | 23.8 | 607-649 | 35 | 0.0493 | 2.73 |

No cracks, corrosion spots or traces of nitrate salt are allowed on the surface.

No cracks, corrosion spots or traces of nitrate salt are allowed on the surface. Peeling, bubbles, surface roughness and local mechanical damage with a depth not exceeding 8% of the nominal wall thickness of the defective part are allowed on the surface; but the maximum depth of the defect cannot exceed 0.5mm, and the total area of the defect does not exceed the total area of the plate 5%.

Peeling, bubbles, surface roughness and local mechanical damage with a depth not exceeding 8% of the nominal wall thickness of the defective part are allowed on the surface; but the maximum depth of the defect cannot exceed 0.5mm, and the total area of the defect does not exceed the total area of the plate 5%. The supplier is allowed to polish the profile longitudinally until the surface is smooth.

The supplier is allowed to polish the profile longitudinally until the surface is smooth. Other requirements: the clients and factory shall formulate their own requirements.

Other requirements: the clients and factory shall formulate their own requirements. 5052 aluminum plate strip is divided into O temper and H temper:

5052 aluminum plate strip is divided into O temper and H temper: 5052-O aluminum plate strip is a product after annealing, that is, a fully soft state, and is used for low-strength aluminum alloy plates obtained by complete annealing.

5052-O aluminum plate strip is a product after annealing, that is, a fully soft state, and is used for low-strength aluminum alloy plates obtained by complete annealing. 5052-H32/H34 aluminum plate strip indicates products whole mechanical properties have been stabilized after work hardening and low-temperature heat treatment. The strength and mechanical properties of H32/H34 aluminum plates are better than O temper annealed. H is the work hardening state, followed by a number indicating the degree of work hardening and softness and hardness. It is used for products whose strength is increased through work hardening. The aluminum sheet may or may not undergo additional heat treatment that reduces the strength after work hardening.

5052-H32/H34 aluminum plate strip indicates products whole mechanical properties have been stabilized after work hardening and low-temperature heat treatment. The strength and mechanical properties of H32/H34 aluminum plates are better than O temper annealed. H is the work hardening state, followed by a number indicating the degree of work hardening and softness and hardness. It is used for products whose strength is increased through work hardening. The aluminum sheet may or may not undergo additional heat treatment that reduces the strength after work hardening.

Tags: 5052 aluminum plate