- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

*(Compliant with IEC 60317/JIS C 3202 Standards)*

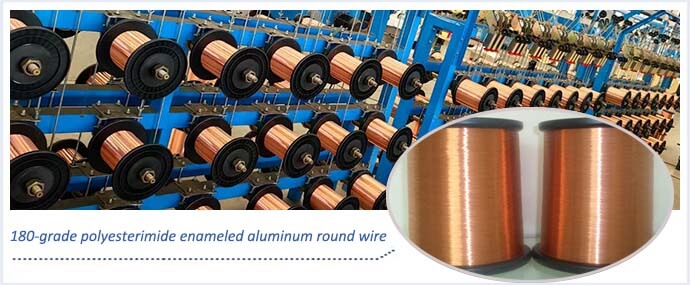

The 180-Class Polyester-Imide Enameled Round Aluminum Wire, as a high-temperature magnet wire, features:

Heat Resistance: 180°C continuous operating temperature (220°C short-term tolerance)

Heat Resistance: 180°C continuous operating temperature (220°C short-term tolerance) Insulation System: Dual-layer polyester-imide structure, resistant to solvents/refrigerants (R134a)

Insulation System: Dual-layer polyester-imide structure, resistant to solvents/refrigerants (R134a) Conductor Advantage: Aluminum resistivity ≤0.0283 Ω·mm²/m (50% lighter than copper)

Conductor Advantage: Aluminum resistivity ≤0.0283 Ω·mm²/m (50% lighter than copper) Mechanical Protection: Enamel withstands ≥210 reciprocating scrape tests (ASTM D2519)

Mechanical Protection: Enamel withstands ≥210 reciprocating scrape tests (ASTM D2519)

| Phase | Requirements | Risk Control |

| Storage | Climate-controlled warehouse (10-30°C) · Humidity monitor (RH≤80%) · Elevated pallet storage | Condensation-induced insulation degradation |

| Transport | Double packaging (moisture-proof film + corrugated box) · Anti-drop pallets · Prohibit co-shipment with chemicals | Mechanical impact causing micro-cracks |

✅1. Cutting & Stripping

Tools: Pneumatic stripper (e.g., Schleuniger 4860) or ceramic-blade wire strippers

Specifications: Strip length ≤15mm · Burr-free cut ends

✅2. Soldering Procedure

Pre-treat 180-Class Polyester-Imide Enameled Round Aluminum Wire with FL-22 flux

Temperature Control: Soldering iron tip ≤300°C (JBC titanium tip recommended) · Duration ≤3 seconds

Post-soldering: Clean residue with isopropanol · Apply UGL-316 conformal coating

✅3. Bending Protection

Minimum bend radius ≥2× wire diameter (e.g., Φ1.0mm wire requires R≥2mm)

Install silicone sleeves (e.g., HellermannTyton SDR-25) at stress points

▶ Operational Monitoring

Current Rating: Adhere to GB/T 7672 aluminum wire ampacity tables (e.g., Φ1.5mm wire ≤18A@90°C)

Overtemperature Protection: Embed PT100 sensors; trigger shutdown at >170°C

▶ Maintenance Inspections

1. Quarterly Checks:

– Insulation Resistance: ≥100 MΩ/km at 20°C (500V DC megger)

– Turn-to-Turn Withstand: 0.5kV/0.5s no breakdown (IEC 60851)

2. Annual Maintenance:

– Thermal imaging of connection points

– Enamel elasticity test (elongation ≥25%)

| Failure Mode | Emergency Action | Root Cause Prevention |

| Localized Enamel Damage | Repair with UV-cure adhesive (Loctite 3922) | Deburr wire channels · Winding tension ≤2N |

| Cold Solder Joint | Resolder + X-ray penetration inspection | Pre-solder oxide etching · Nitrogen-shielded soldering |

| Insulation Aging/Cracking | Replace entire wire segment | Strict temperature control · Triennial TGA analysis |

Reliability of 180-Class Polyester-Imide Enameled Round Aluminum Wire depends on:

🔹Damage-Free Handling – Strict temp/RH control & impact-proof packaging

🔹Precision Processing – Controlled stripping/soldering/bending procedures

🔹Operational Limits – Adherence to current/temperature thresholds

🔹Predictive Maintenance – Data-driven inspection protocols

Original Source:Magnet Wires for Power Industry