- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

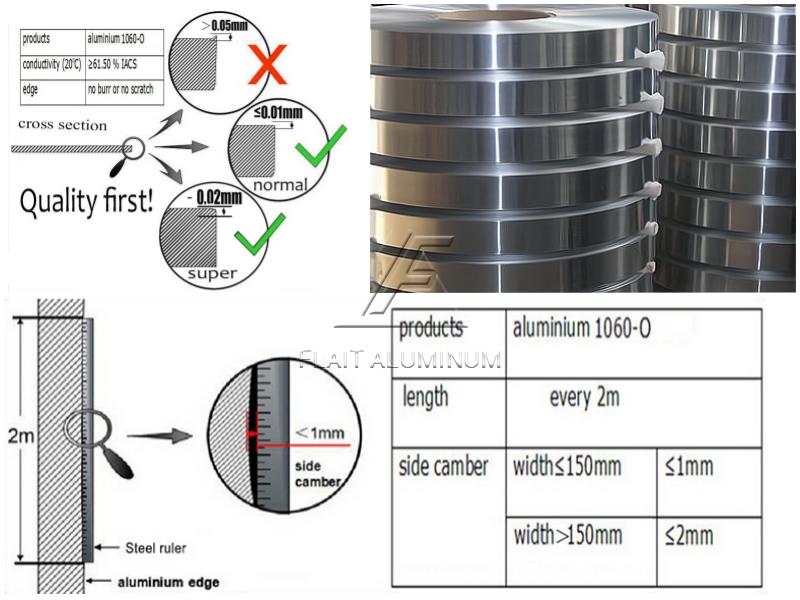

Transformer aluminum strips are divided into different grades, specifications, and states according to their uses. Common grades are: 1060, 1050, 1050A, 1060, 1070, 1070A, 1350, Temper: O temper, thickness between 0.08-3.00. Mainly used in large transformers, solar energy, power industry, high and low voltage windings of dry-type transformers as conductive materials.Click to Order

Aluminum strips and foils for dry-type transformers generally use 1060 O aluminum strips, whose aluminum content reaches more than 99.6%, also known as pure aluminum strips, which belong to a commonly used series in the aluminum strip family. 1060 aluminum strip has good elongation and tensile strength, which can fully meet the conventional processing requirements (stamping, stretching) and high formability. 1060 aluminum strip has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, heat treatment can not strengthen the machinability is not good; can be gas welding, hydrogen atom welding and contact welding, not easy to braze; easy to withstand various pressures Processing and extension, bending.

| Alloy | 1060 O aluminum strip |

| Temper | O |

| Thickness(mm) | 0.2-3.5 |

| Width(mm) | 10-1600 |

| Surface treatment | Mill finish |

| Electrical Conductivity | Transformer made of 1060 O aluminum in annealed condition is guaranteed to be better than 62% ACS |

| Application | Mainly used in high and low voltage windings of dry-type transformers as conductive materials |

| Alloy | Si | Fe | Mg | Zn | Mn | Ti | Cu | V | Al |

| 1060 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0022 | 0.0039 | Remainder |

| Alloy | Temper | Thickness(mm) | Mechanical properties | ||

| Tensile Strength(Mpa)standard value | Resistivity standard value | Elongation(%)A50 | |||

| 1060 | O | 0.2-3.5 | 70 | 0.028 | 30 |

1.1060 is a relatively commonly used series of products, the production process is relatively simple, the technology is mature, and the price is relatively cheap.

1.1060 is a relatively commonly used series of products, the production process is relatively simple, the technology is mature, and the price is relatively cheap. 2.1060-O temper transformer aluminum strip has a high aluminum content, usually above 99.6%, and has good electrical conductivity.

2.1060-O temper transformer aluminum strip has a high aluminum content, usually above 99.6%, and has good electrical conductivity. 3.It has good elongation and tensile strength, can fully meet the requirements of conventional processing, is easy to withstand various pressure processing and stretching, bending, and has high formability.

3.It has good elongation and tensile strength, can fully meet the requirements of conventional processing, is easy to withstand various pressure processing and stretching, bending, and has high formability. 4.It has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but its strength is low, and heat treatment cannot strengthen its machinability.

4.It has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but its strength is low, and heat treatment cannot strengthen its machinability. 5.It can be gas welded, hydrogen atom welded and contact welded, but not easy to braze.

5.It can be gas welded, hydrogen atom welded and contact welded, but not easy to braze.

Original Source: Transformer Aluminum Strip

Tags:1060 aluminum coil