- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

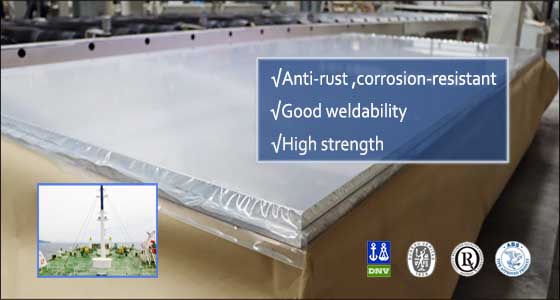

Today, as the shipbuilding industry pursues lightweight and corrosion resistance, aluminum alloy has become the core material for ship design. 5086 marine aluminum plate is gradually replacing traditional 5052 marine aluminum plate with high strength, super seawater corrosion resistance and excellent welding performance, becoming the preferred material for the shipbuilding industry.

✅ Corrosion resistance

The magnesium content of 5086 aluminum plate is as high as 4.5%-5.5% (5052 aluminum plate is only 2.2%-2.8%), forming a dense magnesium oxide layer, which increases the resistance to salt water corrosion by more than 40%. 5086 H116 aluminum plate is specially developed for high-salt environment, which can resist seawater erosion for more than 20 years and greatly reduce maintenance costs.

Comparative experiments show that in simulated seawater spray, 5052 aluminum plate has pitting after 3 months, while 5086 keeps the surface intact.

✅Strength and safety

5086 aluminum plate is strengthened by cold machining, and its tensile strength reaches 173-305MPa, which is higher than 170-244MPa of 5052 aluminum plate. Its elastic modulus is smaller, and it can absorb more than 70% of the impact stress, significantly reducing the risk of hull fracture in storms.

✅Welding process

The strength retention rate of 5086 aluminum plate after welding exceeds 90%, while the weld of 5052 aluminum plate is prone to softening zone. The cruise ship deck built with 5086 reduces the welding hours by 30% and does not require secondary reinforcement.

| Index | 5086 Marine Aluminum Plate | 5052 Marine Aluminum Plate |

| Magnesium content | 4.5%-5.5% | 2.2%-2.8% |

| Tensile Strength (MPa) | 173-305 | 170-244 |

| Salt spray resistance test | >2000 hours without corrosion | Pitting occurred after 800 hours |

| Recommended Marine Parts | Deck/bottom plating/engine pedestal | Interior panels/chimneys/rivets |

✅ Designed for extreme environments

Minesweepers and icebreakers: The non-magnetic properties of 5086 marine aluminum plate avoid triggering mines, and there is no risk of brittle cracking at low temperatures of -50℃.

LNG carriers: With 5086 H116 aluminum plate, the low-temperature liquefied gas tank is 35% lighter than 5052 aluminum plate.

✅ Full life cycle cost revolution

Ship switching to 5086 marine aluminum plate can extend the service life and reduce the cost of use

✓ Fuel consumption reduced by 12% (lightweight effect)

✓ Maintenance cycle extended from 2 years to 5 years

✓ Total cost reduced by 28% in 20 years

As a company with many years of experience in the R&D and production of marine aluminum plates, our products have been certified by global classification societies. We provide:

✓ Full-process customization: Customizable production of ultra-wide plates up to 2650mm in width (covering 95% of hull requirements), flexible cutting of thickness from 0.5 to 600mm.

✓ Certification system: Products are certified by CCS, DNV, BV, and ABS and meet international standards.

✓ Butler service: Fast quotation, 35-day delivery, support T/T 30% deposit to lock production capacity.

Original Source:Marine Grade Aluminum Sheet Plate