- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

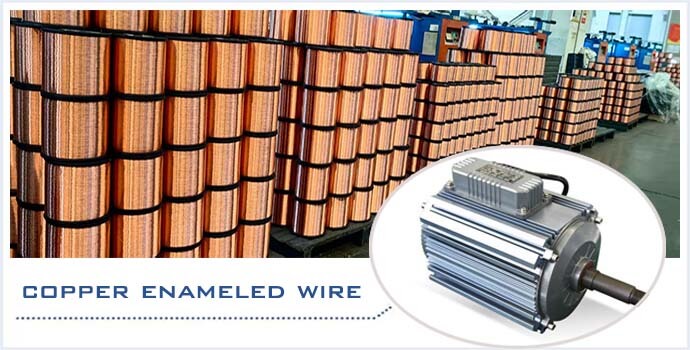

To meet the stringent requirements of industrial motors, new energy vehicles, smart home appliances and other fields, we have launched a full range of high-performance copper enameled wires, covering 0.05mm-3.0mm wire diameters, supporting UL/CSA/IEC certification, and helping high-efficiency motor design!

High frequency and low loss: Ultra-fine wire diameter (starting from 0.05mm) multi-strand twisting, reducing skin effect, and adapting to high-frequency motors.

High frequency and low loss: Ultra-fine wire diameter (starting from 0.05mm) multi-strand twisting, reducing skin effect, and adapting to high-frequency motors. Temperature resistance upgrade: Full temperature range coverage from H grade (180℃) to C grade (220℃), resistant to extreme working conditions.

Temperature resistance upgrade: Full temperature range coverage from H grade (180℃) to C grade (220℃), resistant to extreme working conditions. Flexible and durable: Anti-bending ≥10 times (ASTM D4565 standard), winding does not break.

Flexible and durable: Anti-bending ≥10 times (ASTM D4565 standard), winding does not break. Environmental certification: RoHS/REACH/SVHC compliance, worry-free circulation in the global market.

Environmental certification: RoHS/REACH/SVHC compliance, worry-free circulation in the global market.

| Model | Wire diameter range | Insulation material | Temperature resistance level | Application |

| QZY-180 | 0.05-1.5mm | Polyurethane (UEW) | H grade (180℃) | High frequency motor, drone motor |

| QXYB-220 | 0.1-2.5mm | Polyimide (PI) | C grade (220℃) | Electric vehicle drive motor |

| QZ-155 | 0.2-3.0mm | Polyesterimide + polyamideimide | F grade (155℃) | Industrial variable frequency motor, compressor |

| SQZY-180 | 0.08-1.0mm | Silver-plated copper wire + polyurethane | H grade (180℃) | High-precision servo motor, medical equipment |

✅ 1. High frequency and low loss scenarios (such as drone motors)

Recommended model: QZY-180 (0.1mm×100 stranded wire)

Advantages: Skin loss is reduced by 40%, and winding efficiency is increased by 30%!

✅ 2. High temperature and high load scenarios (such as electric vehicle drive motors)

Recommended model: QXYB-220 (0.25mm corona-resistant coating)

Advantages: 220℃ continuous operation without softening, passed 3000h durability test!

✅ 3. Chemical corrosion resistance scenarios (such as chemical pump motors)

Recommended model: QZ-155 (oil/freon resistant)

Advantages: Acid and alkali corrosion resistance level reaches IP67, and life is extended by 50%!

✅ Customized service: support flexible customization of wire diameter, twisting method, coating thickness

✅ Global logistics: 15-day fast delivery, covering Europe, America, Southeast Asia, and the Middle East

✅ Technical support: free winding process guidance and thermal simulation reports

Q: How to choose the wire diameter?

A: According to the current density (3~6A/mm² is recommended) and space constraints, 0.1mm~0.5mm multi-strand twisting scheme is recommended.

Q: What kind of coating is needed for high temperature environment?

A: Select QXYB-220 polyimide above 220℃, and select QZ-155 composite coating for 155℃~180℃.

Q: Minimum order quantity?

A: Standard model starts at 10kg, and small batch samples are supported!

Fuente original:Magnet Wires for Power Industry