- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

Today, when the power density of new energy vehicle motors exceeds 5kW/kg, traditional F-class (155℃) enameled wires are facing: high-frequency inverters cause local temperature rises of more than 170℃; 800V high-voltage systems increase the corona resistance requirements of the insulation layer by 300%.

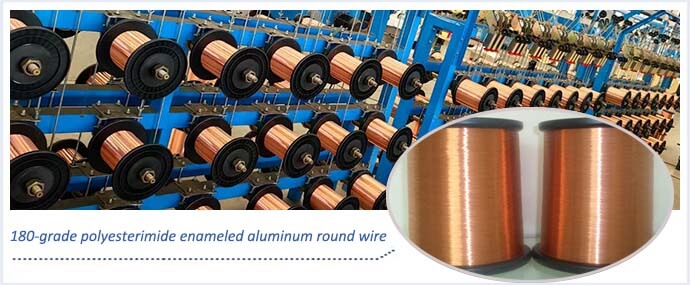

As a professional enameled wire supplier, Flait Aluminum uses nano-modified polyester imide resin to develop H-class (180℃) high temperature resistant enameled wire products certified by UL 1441, including QZYL-180 enameled aluminum wire and QZY-180 enameled copper wire.

| Parameter Category | Test Standards | QZYL/QZY-180 indicators | Industry Standards |

| Conductor diameter | IEC 60317-0-1 | 0.10-6.50mm±1% | ±2% |

| Maximum outer diameter | UL 1441 | +0.03mm | +0.05mm |

| Breakdown voltage | GB/T 4074.5 | ≥3000V(0.3mm) | ≥2500V |

| Elongation | ASTM B193 | ≥30%(copper) | ≥25% |

| Thermal shock | IEC 60851-3 | 3D@180℃ no cracks | 2D@180℃ |

Electrical performance table by specification

Electrical performance table by specification| Type | Nominal diameter(mm) | DC resistance (Ω/km) | Current density (A/mm²) |

| QZYL/QZY-180-0.5 | 0.5 | 89.2 | 6.8 |

| QZYL/QZY-180-1.2 | 1.2 | 15.3 | 8.2 |

| QZYL/QZY-180-2.0 | 2 | 5.61 | 9.5 |

| QZYL/QZY-180-3.0SQ | 3.0×5.0 (rectangular wire) | 2.33 | 12.1 |

Environmental adaptability parameters

Environmental adaptability parameters| Test items | Condition | QZYL/QZY-180 Results | Certification Standards |

| Chemical resistance | Soak in engine oil for 72h@150℃ | ΔR≤3% | ISO 6722-1 |

| Resistance to moisture and heat aging | 1000h@85℃/85%RH | No delamination or shedding | IEC 60068-2-78 |

| Hot and cold cycle | -40℃↔180℃ 100 times | Insulation intact | AEC-Q200 |

🔹Case 1: A TOP3 car company drive motor project

Using FL-H180-2.5SQ flat wire

Measured data: The winding temperature under peak power dropped from 162℃ to 148℃; the aging rate of the insulation layer was reduced to 1/3 of that of Class F products.

🔹Case 2: Industrial variable frequency motor transformation

After replacing the original Class F enameled wire: the allowable overload current increased by 15%; the expected life was extended from 5 years to 8 years.

Conductor optimization:

◆ Optional copper purity: 4N (99.99%) to 6N (99.9999%)

◆ Special-shaped cross-section: 12 options including rectangular and hollow

◆ Coating system: triple coating process (primer + intermediate layer + self-lubricating topcoat); color supports full customization of RAL color cards

✅Online detection: 100% passes:

Laser diameter gauge (accuracy ±0.001mm)

Partial discharge detection (sensitivity ≤5pC)

✅Traceability system: Each axis product comes with an independent QR code, including:

Raw material batch

Process parameter curve

Detection video clip

Original Source:Magnet Wires for Power Industry