- Email: sales@flait-aluminum.com

- Tel: 0086-13203837398

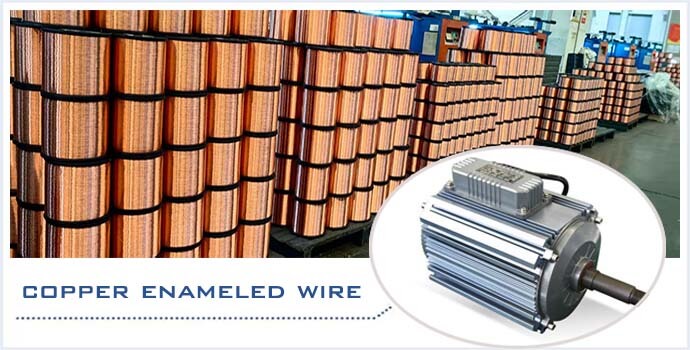

Enameled wire is the essential component of motor windings. Its thin insulating layer not only guarantees electrical isolation between coils but also ensures efficient current conduction, serving as the core foundational material for the efficient and reliable operation of motors. The era of high-speed motors has fully arrived. While increased rotational speed brings leaps in efficiency, it imposes unprecedented stringent demands on the core material—enameled wire—facing extreme temperatures, high-frequency electrical stresses, and severe mechanical vibration.

Flait Aluminum’s new generation of high-performance enameled wire is designed specifically for high-speed motor winding applications, helping your motor break through performance limits!

Heat Resistance & Thermal Stability

Heat Resistance & Thermal Stability

✅ Key Materials: High-purity conductor paired with specialty coatings: Polyesterimide (PEI), Polyimide (PI), or Composite.

🔹Core Advantage: Ultra-high heat resistance ratings from Class H (180°C) to Class C (220°C+), easily withstanding sustained high temperatures and frequent overload surges inside high-speed motors. Excellent thermal aging life ensures long-term operational reliability.

✔Application Suggestion: The preferred choice for windings in high-temperature core zones, such as New Energy Vehicle (NEV) traction motors and high-power industrial inverter-driven motors, ensuring insulation safety and stable performance at elevated temperatures.

Corona Resistance & High-Frequency Performance

Corona Resistance & High-Frequency Performance

✅ Key Technology: Special coating formulations and precision coating processes significantly enhance corona resistance.

🔹Core Advantage: Effectively resists partial discharge erosion under the PWM high-frequency pulse voltage from inverters, substantially reducing the risk of insulation aging. Low dielectric loss minimizes energy loss and heat generation at high frequencies.

✔Application Suggestion: Essential for inverter-driven motors (EV, Servo, Compressor, etc.), extending motor lifespan in harsh electrical environments and improving system energy efficiency.

Mechanical Strength & Flexibility

Mechanical Strength & Flexibility

✅ Key Process: Optimized conductor toughness and coating adhesion technology.

🔹Core Advantage: Resists stretching, bending, and friction during high-speed winding and insertion processes, reducing film damage and pinholes. Maintains necessary flexibility to adapt to compact and complex coil designs.

✔Application Suggestion: The ideal partner for automated high-speed winding production, ensuring high yield rates, especially suitable for precision motor windings with high slot fill factors and complex wire shapes.

Low Loss & High Efficiency

Low Loss & High Efficiency

✅ Key Foundation: Utilizes high-purity electrolytic copper/aluminum conductors with high surface smoothness.

🔹Core Advantage: Extremely low conductor AC/DC resistance loss (Low Loss) and minimized skin effect impact, combined with low dielectric loss coating, collectively enable highly efficient electrical energy conversion.

✔Application Suggestion: For applications demanding ultimate efficiency (e.g., high-efficiency energy-saving motors, extended EV range), choosing FlaiT low-loss enameled wire is the foundational guarantee for achieving higher energy efficiency goals.

Adhesion & Chemical Compatibility

Adhesion & Chemical Compatibility✅ Key Characteristic: Coating bonds tightly to the conductor and withstands common impregnating resins and cooling media.

🔹Core Advantage: Ensures the integrity of the entire insulation system (enamel film + impregnating varnish), resisting environmental stresses (heat, cold, humidity, oil, refrigerant, etc.).

✔Application Suggestion: Ensures long-term reliability of motors under various complex operating conditions and different encapsulation processes.

Electric Vehicle Traction Motors: First choice is Polyesterimide/Polyimide composite enameled wire with Class 200+ heat resistance, ultra-high corona resistance, and low loss. Addresses high power density, high-frequency PWM, and high-temperature environments.

Electric Vehicle Traction Motors: First choice is Polyesterimide/Polyimide composite enameled wire with Class 200+ heat resistance, ultra-high corona resistance, and low loss. Addresses high power density, high-frequency PWM, and high-temperature environments. Industrial Servo Motors/Spindle Motors: Recommend enameled wire with high heat resistance (≥ Class 180), high mechanical strength, and low loss. Meets demanding requirements for high speed, high precision, and frequent start-stop cycles.

Industrial Servo Motors/Spindle Motors: Recommend enameled wire with high heat resistance (≥ Class 180), high mechanical strength, and low loss. Meets demanding requirements for high speed, high precision, and frequent start-stop cycles. High-Speed Compressor Motors: Select specialized enameled wire with refrigerant resistance, high heat resistance, and corona resistance. Resists refrigerant erosion and high-temperature/high-pressure challenges.

High-Speed Compressor Motors: Select specialized enameled wire with refrigerant resistance, high heat resistance, and corona resistance. Resists refrigerant erosion and high-temperature/high-pressure challenges. High-Efficiency Industrial Motors: Choose enameled wire (e.g., Polyesterimide) with Class H or higher heat resistance and low loss. Improves efficiency class and reduces operating costs.

High-Efficiency Industrial Motors: Choose enameled wire (e.g., Polyesterimide) with Class H or higher heat resistance and low loss. Improves efficiency class and reduces operating costs.

Higher Motor Reliability: Withstands high temperature, corona, and vibration, extending service life.

Higher Motor Reliability: Withstands high temperature, corona, and vibration, extending service life. Superior Efficiency Performance: Low-loss design enhances energy efficiency and reduces consumption.

Superior Efficiency Performance: Low-loss design enhances energy efficiency and reduces consumption. Increased Power Density: High-temperature resistance enables more compact designs, unlocking space potential.

Increased Power Density: High-temperature resistance enables more compact designs, unlocking space potential. Optimized Production Yield: Excellent mechanical properties adapt to high-speed automated production.

Optimized Production Yield: Excellent mechanical properties adapt to high-speed automated production. Future-Oriented Technology: Meets increasingly stringent demands for higher speeds and greater efficiency.

Future-Oriented Technology: Meets increasingly stringent demands for higher speeds and greater efficiency.

Original Source:Magnet Wires for Power Industry